The stamping production process is a process of stamping a steel plate into a car body, that is, a body cover and a structural part. Stamping is a traditional material forming process. With the development of the automotive industry, stamping process is widely used in manufacturing. The stamping process greatly improves the accuracy and efficiency of material molding. Take the automotive industry as an example, stamping can punch a part every 5s, and the accuracy of the parts can generally reach more than 95%.

The development of stamping technology depends on the advancement of mold technology. Since the 1960s, computer technology has improved and its application in the manufacturing industry. CAD, CAE, CAM and other computer-aided systems, automotive mold development and manufacturing efficiency have greatly improved The machining accuracy of the large 5-axis machining center reaches 0.01mm, and the servo press also brings great convenience to mold debugging and part molding.

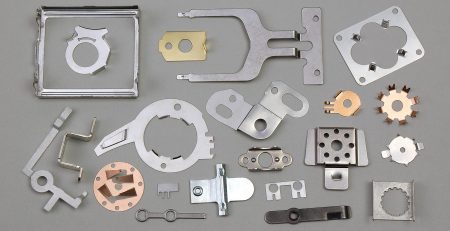

The stamping process of automobile parts generally includes four processes: drawing process, trimming process, punching process and flanging process. Each process corresponds to a set of molds. Sometimes in order to save costs, a set of molds is made for the subsequent trimming and punching processes and compressed into three steps.

The stamping process of automobile enterprises is basically similar, but the stamping technology of different materials is different. At present, under the background of automobile lightweight, aluminum body is used by more and more automobile enterprises. Due to the difference of material properties between aluminum and steel, aluminum body has some technical difficulties in stamping, and the manufacture of automobile mould also needs different surface treatment.