All that you need to know about sheet metal stamping dies

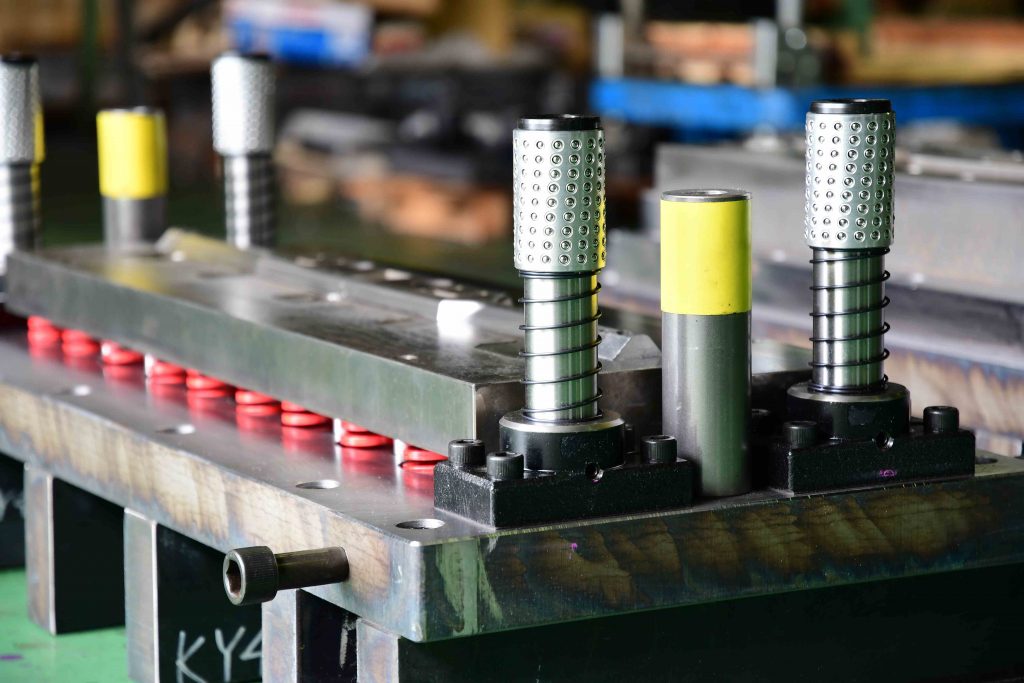

The process of metal stamping involves cutting raw sheet metal into specific shapes and designs, as required by different industries. Metal stamping companies use different types of dies and metal stamping presses for this process. The die or dies are first inserted into the stamping press. Force is then applied inside to convert the flat sheet metal into the shape or size required. Industries use different kinds of sheet metal stamping dies based on their requirements. Here, you will get to know more about the meaning, types and application of these stamping dies.

Process of die stamping – A brief overview

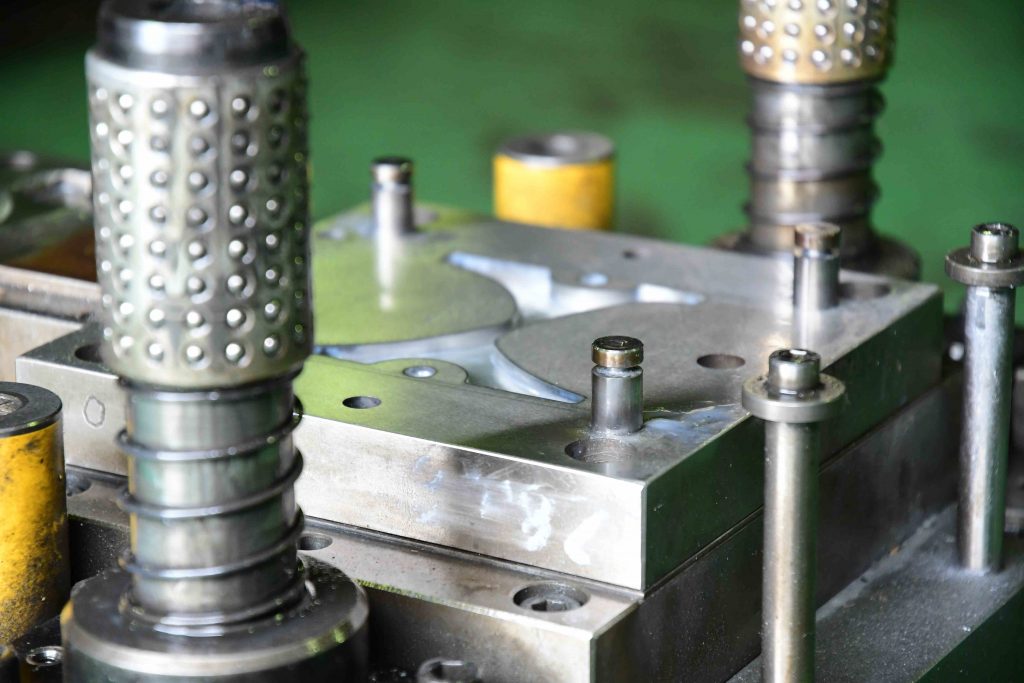

A metal stamping die process is where the raw sheet metal (also known as metal blanks or tool steel) undergoes a forming process with the help of single or multiple dies to form a finished metal structure of the desired shape or size. This metal sheet is exposed to a lot of force inside the press to create accurate cuts and bends. A metal stamping die process can be used to create small or large pieces based on their application.

Sometimes, custom metal stamping dies are used to create customized shapes and designs required by clients. Due to the level of customizations followed here, this is slightly more expensive than the normal metal stamping die process. The process of using sheet metal stamping dies is possible only because of a series of complex but repeated techniques applied to the raw metal blanks. These techniques include punching, blanking, piercing, coining and more.

Classification of sheet metal stamping dies

While you may find many categories of normal and custom metal stamping dies in the industry today, they are all broadly classified into two main types. They are:

Single-Station Sheet Metal Stamping Dies

Here, a metal stamping die press is used for a single operation. The workpiece on which the die does its shape and designs, has to be removed from the press for the next operation to continue. This is why a single-station stamping die is also known as a single-stage or single-operation stamping die. The most common types of single-station sheet metal stamping dies are:

- Simple Stamping Dies – Every stroke of the press is used for one operation here. As the name implies, these dies are used for simple or basic operations. They may not be very effective to be used as large-scale or customized operations.

- Compound Stamping Dies – Here, a single stroke of the stamping die press can perform multiple operations. They are quicker, more accurate and more reliable than simple dies. So, a custom metal stamping die can be used for this purpose, in addition to the dies being used for large-scale or complex operations. They are mostly used for cutting jobs, but are not very effective for forming jobs.

- Combination Dies – Though they can perform multiple operations for every stroke of the press like compound dies, they can be used for cutting and forming jobs (blanking, piercing, bending and more.

Multi-Station Sheet Metal Stamping Dies

When the workpiece or the raw sheet metal needs to be moved to different stations, multi-station sheet metal stamping dies are used. These dies are usually designed in the form of a series, where each series is exclusive to a particular station and job. The main types of multi-station stamping dies are:

- Progressive Stamping Dies – Here, the operation takes place in the sequence of the stations. Once the work is completed in one station, the workpiece is then transported to the next station for the rest of the procedure. As the sheet metal passes through these stations, it is cut, formed and bent to form the desired shape and size. At the final station, the cut and designed portion is separated from the workpiece. These are suitable for simple and small projects.

- Transfer Stamping Dies – The process here is similar to the one followed in progressive stamping dies. Here also, the metal is moved to various stations after the work is completed in one. However, the major difference in this stage is that the piece that is worked on is cut off from the main workpiece before it is moved to the next station. The metal parts are moved to the stations manually or using mechanical conveyor belts or through robotic means in big industries. This is slightly more effective and quicker than the progressive stamping die process, and is suitable for large and complex projects or components.

Metal stamping die processes

Whether you use regular stamping dies or a custom metal stamping die, the processes or techniques used on the metal workpiece are the same. These processes are broadly classified into two – forming dies and cutting dies.

Forming Dies

Here, sheet metals or blanks undergo various compression techniques to be formed into specific shapes or designs. The techniques used in forming dies are:

- Bending – Blanks are cut into U, V, or L shapes by creating the right bend

- Flanging – Workpiece is bent along a curved axis with the help of tension and compression processes

- Drawing – Material of the desired shape displaces the workpiece to get the perfect shape and dimensions of the final structure

- Stretching – Tension and thinning techniques help in making the workpiece very smooth

- Coining – Thickness reduced by exposing the workpiece to extreme pressure while squeezing it

- Ironing – Similar to coining; used to reduce wall thickness of the workpiece considerably

Cutting Dies

Mostly referred to as the shearing process, this technique involves cutting or separating the metal from the workpiece. The techniques used with these dies are:

- Shearing – Parallel and angle cuts made on the metal

- Blanking – Removing the strip of metal to be worked upon from the workpiece carefully, following the dimensions and contours

- Trimming – Fine-tuning the sides to get the perfect shape as desired

- Notching – Used to help with the bending process to get customized shapes

- Piercing – Similar to blanking, but the part cut out is useless, and work has to be done on the remaining part

Though there are many other types of sheet metal stamping dies available in the market today, the ones described above are the most popular and commonly-used.