Application of Sheet Metal Parts: Understanding its Significance in Different Industries

As an integral part of many industries, sheet metal parts play an important role. Because these parts are versatile, durable, and affordable, they have become a popular choice for a wide range of applications. Here, we will take a closer look at the different industries that utilize sheet metal parts as well as the advantages they offer in terms of performance and efficiency.

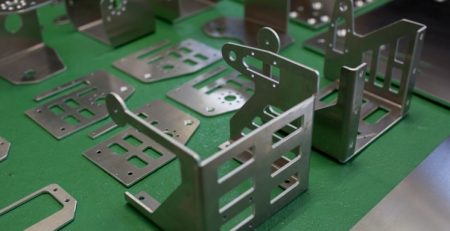

Introduction to Sheet Metal Parts

Let me share some basic information about sheet metal parts so that we may better understand what they are and the different application of sheet metal parts they can be used for. The sheet metal parts are thin, flat pieces of metal that are cut, bent, and formed into various shapes and sizes based on the size and shape of the sheet of metal. Usually, these parts are made of metals like steel, aluminum, brass, copper, as well as other types of metals.

Due to the excellent properties of sheet metal parts, which include the ability to be strong, durable, flexible, and easy to manufacture, they are widely used in a wide variety of industries. It is worth noting that sheet metal parts can also be manufactured in large quantities, thus making them an ideal solution for a wide variety of applications because of their cost-effectiveness.

Applications of Sheet Metal Parts

- Automotive Industry

It has been known for many years that sheet metal parts have been used in the automotive industry. In order to manufacture cars, doors, hoods, fenders, and other components of the cars, they are essential. Parts made of sheet metal are advantageous to the automotive industry for several reasons, including their strength, durability, and ability to withstand extreme temperatures and harsh weather conditions.

The other advantage of sheet metal parts is that they are lightweight, so they are suitable for vehicles in which weight is an important factor to keep in mind. The advantages of sheet metal parts are that they are easily formed and shaped so that they can be customized for each vehicle according to its unique design requirements.

- Aerospace Industry

The aerospace industry is another sector that heavily relies on the use of sheet metal parts for the production of its products. As a result, these parts are widely used in the construction of airplanes, helicopters, and other aircrafts. With their excellent strength-to-weight ratios, sheet metal parts are ideal for use in aircraft where weight is a significant concern because they have a high strength-to-weight ratio.

Additionally, Application of sheet metal parts can withstand extreme temperatures and high pressure, making them ideal for use in aircraft engines and other critical components. Moreover, sheet metal parts can be easily fabricated to meet the specific design requirements of different aircraft.

- Construction Industry

As well as being widely used in the construction industry, sheet metal parts are also used in the automotive industry. Roof systems, gutter systems, flashing systems, and other components are produced by using them. The construction industry can benefit greatly from the use of sheet metal parts, as they have several advantages, including their durability, corrosion resistance, and ease of installation.

Aside from this, sheet metal parts are available in a variety of colors and finishes, which makes them ideal for use in a variety of architectural designs. In addition, sheet metal parts are readily available for forming and shaping to meet the specific requirements of a wide range of construction projects, which makes them an excellent choice.

- Medical Industry

The use of sheet metal parts in the medical industry is increasing as more and more medical devices and equipment are being manufactured using sheet metal parts. As these parts are extremely strong and durable, they are ideal for the use in critical medical applications due to their strength and durability.

Additionally, sheet metal parts are very easy to clean and sterilize, which makes them an ideal material for use in medical devices that require high levels of hygiene and cleanliness. Furthermore, sheet metal parts can also be easily fabricated to meet the specific design requirements of different medical devices which can be found in a wide range of applications.

Advantages of Sheet Metal Parts

- Durability: Parts made of sheet metal are highly durable and able to withstand harsh environmental conditions as well as daily wear and tear.

- Versatility: Parts made out of sheet metal can be cut, fabricated, and formed into a variety of shapes and sizes, making them very versatile and adaptable to a wide range of applications.

- Cost-effectiveness: Parts made out of sheet metal can be cut, fabricated, and formed into a variety of shapes and sizes, making them very versatile and adaptable to a wide range of applications.

- Sustainability: Various industries use sheet metal parts because they are highly recyclable and offer an environmentally friendly option for various uses.

Conclusion

Parts made of sheet metal are an essential component of a wide range of industries, such as the automobile, aerospace, construction, and medical field. The durability, versatility, cost-effectiveness, and sustainability of these materials make them a great alternative to other materials, especially when compared to other materials. In a world where industries are continually evolving and growing, sheet metal parts will continue to have a significant role to play.