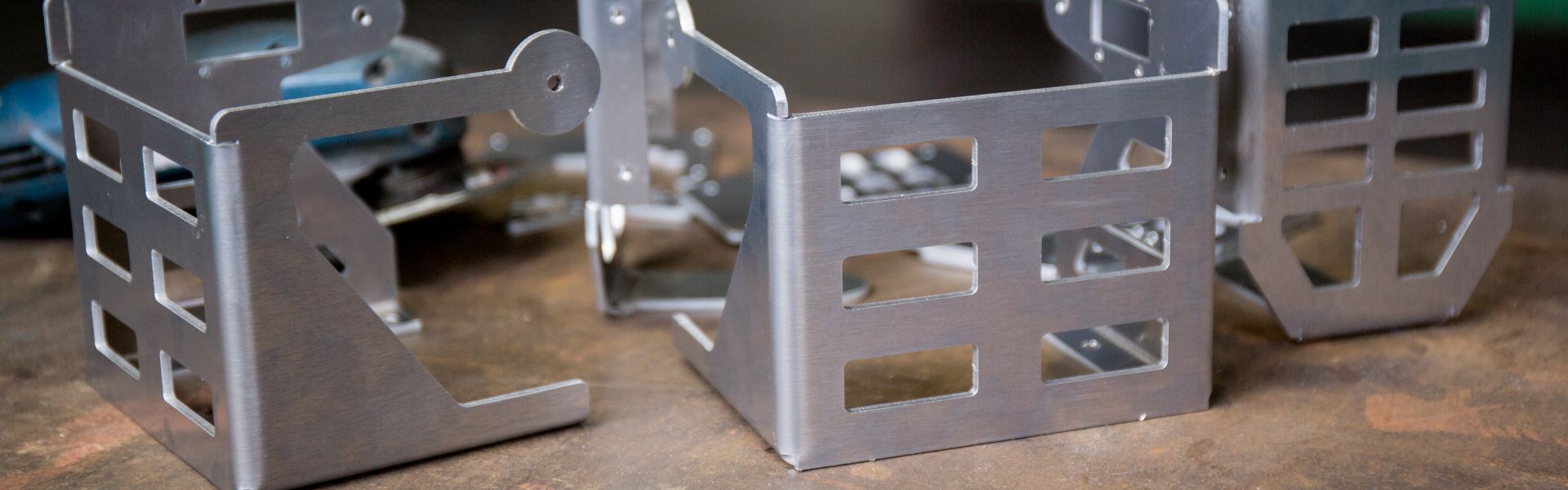

Stainless Steel Stampings in China

After more than 15 years of rich experience accumulation, TenRal as a leader in the manufacturing industry of stainless steel stamping parts in China, has always adhered to the persistent pursuit of quality. We know that every stainless steel stamping part represents the expectation and trust of our customers, so we always adhere to the principle of quality first, and require ourselves to the highest standards, striving to provide customers with the best quality products. We are committed to meeting the current needs of our customers, and look forward to establishing long-term stable cooperative relations with more customers to create a better future together.

Characteristics of stainless steel stamping parts

The unique properties of stainless steel, such as its wide range of grades and temperatures, are fully manifested in stamping processes, sheet metal fabrication processes, and CNC machining processes. This material is widely acclaimed for its exceptional oxidation resistance, light retention, and rust resistance. Its visual aesthetics enhance the overall aesthetic value of the product, making it highly sought after in the manufacturing industry. Stainless steel not only exhibits excellent durability and strength but also demonstrates remarkable corrosion resistance and plasticity, enabling it to maintain consistent performance across diverse environments.

- Enhanced heat resistance: It is composed of a significant amount of chromium and nickel, making it an exceptional stainless steel with superior heat stress resistance.

- Aesthetically pleasing: Its sleek and mirror-like appearance can be further enhanced through polishing to achieve a higher level of finish or by selecting specific materials.

- Health benefits: Due to its easy-to-clean nature, it is highly favored in the pharmaceutical and food industries.

Grades of stainless steel

The term “stainless steel” encompasses not just one specific type, but over a hundred varieties of industrial stainless steel, each engineered to excel in its respective application field. Selecting the appropriate grade of stainless steel is the initial step towards product development.

- 200 Series: Manganese is widely utilized as a cost-effective alternative to nickel in order to overcome its poor corrosion resistance. This series includes grades 201 and 202.

- 300 Series: Represented by grade 304, this series offers suitable tensile properties and excellent corrosion resistance. The addition of molybdenum enhances both strength and corrosion resistance, exemplified by grade 316.

- 400 Series: Comprising ferritic and martensitic stainless steel, this series eliminates the use of manganese. Grade 409 serves as a representative example.

- 500 Series: Consisting of heat-resistant chrome alloy steel.

- 600 Series: Characterized by martensitic precipitation-hardened stainless steel.

The ISO9001-certified TenRal, as a manufacturer and supplier of metal stamping parts, has actively participated in customer projects from development to mass production. With its unwavering commitment to reliable quality and a highly professional team, it stands out as the optimal choice for customers.