Precision Metal Stamping Services

TENRAL Is a manufacturer of metal stamping parts located in China, with the ISO9001 quality standard certification. Our stamping workshop covers over 46,000 square feet, which includes stamping, sheet metal fabrication, powder coating, and mold departments. The stamping capacity varies from 32 tons to 110 tons, and the hydraulic press varies from 80 tons to 200 tons. We offer custom commercial metal stamping solutions, including simple and complex designs.

Our internal tool department uses the stamping dies required for advanced tool steel fabrication, which enables us to deliver high quality products with the required tolerances. We also have other sheet metal manufacturing tools such as welding fixtures that are manufactured in our workshop.

What is Metal Stamping?

As the name implies, the process involves the application of high amounts of pressure to flat metal sheets so that they can be turned into a specific shape. A complex manufacturing process such as punching, blanking, embossing, coining, flanging, piercing, and bending entails a number of steps and techniques. In order to make a large number of identical metal components, a high-speed and low-cost manufacturing process is used. During the stamping process, the part can be shaped to the desired shape with the use of one single stroke of the stamping press, or it can involve a series of stages where progressive dies are used to gradually shape the component. Although it is generally done using sheet metal in the stamping process, there are other flat materials that can also be shaped using the stamping process.

With the help of dies and stamping presses, flat sheet metal can be turned into a desired part or component by using a process that is also known as ‘pressing’ or a cold-forming process. In the stamping press, sheet metal blanks are fed into a tool and die surface that creates the required shape from the blanks that are fed into the press. In terms of metal forming, stamping refers to the process in which a manufacturer uses custom tooling and stamping techniques to produce parts that meet the specifications of their customers. Several industries use this process in order to meet the demand of high volume production and to produce identical precision parts in large quantities.

Metal Stamping Capabilities

We offer a variety of metal stamping methods to ensure that customers get the best manufacturing solution. There are also other specialized techniques within these categories, such as deep drawing, hydroforming, and transfer stamping which have specific applications and advantages depending on the specifics of a given project.

- Blanking

- Coining

- Punching

- Embossing

- Bending

- Deep Draw Stamping

- Progressive Die Stamping

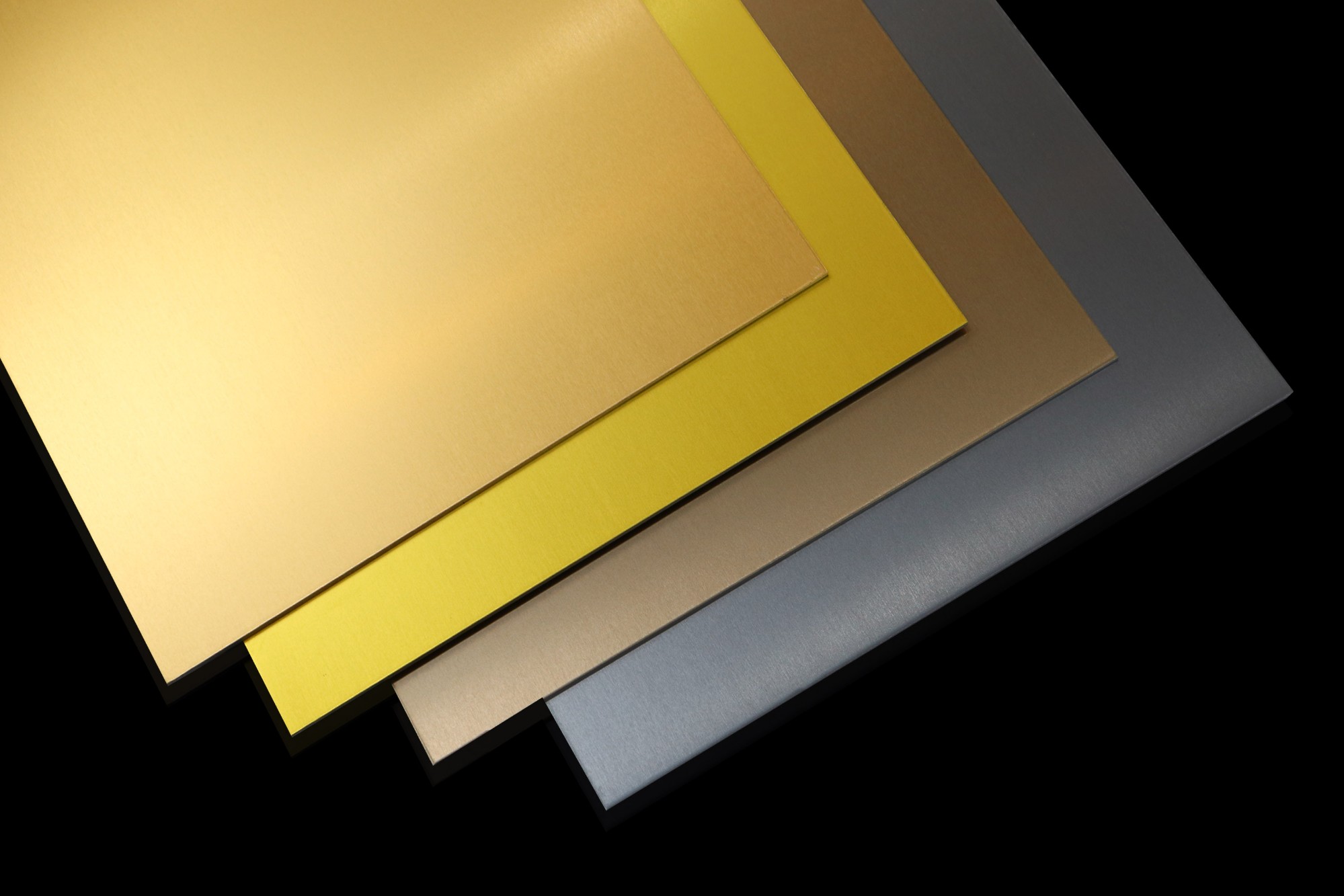

Metal Stamping Materials

In manufacturing and fabrication, a diverse selection of alloys and metals are available in sheet form. The choice of material to use depends on various factors, including weldability, formability, strength, weight, cost, and the corrosion resistance of the material.

- Stainless steel 301

- Stainless steel 304

- Stainless steel 316

- Stainless Steel 430

- Stainless Steel 409

Learn more about Stainless Steel Stamping.

- Aluminum 1050

- Aluminum 5052

- Aluminum 6061

Learn more about aluminum Stamping.

Industrial Applications

TenraL has been designing and manufacturing various complex and precise metal parts for many industries, such as automotive, lighting, plumbing and HVAC, energy, furniture, marine, appliances, electrical, agriculture, entertainment, industrial equipment . We use the industry’s top innovative equipment and knowledgeable people to serve these different segments of the market.

- Automotive

- HVAC

- Furniture

- Agricultural

- Lighting

- Energy

- Appliances

- Recreational

- Marine

- Construction

- Electrical

- Industrial equipment

Quality Policy

As a leading supplier of metal stamping, we always take quality as our business policy. From the procurement of raw materials to the manufacture of finished products, all our employees are responsible for them and take every product seriously. Our engineers work closely with our inspectors to establish product quality documents from the very beginning, documenting the manufacturing process of each product. We always follow the ISO9001 quality requirements, control the quality of each product.

Metal Finishing Services

Tenral provides metal finishing services, including steel, stainless steel, aluminum, brass, etc. No matter which material it is, we understand their characteristics and combine the customer’s manufacturing requirements to quickly find the most suitable metal finishing solution.

- Annealing

- Anodizing

- Deburring

- Electropolishing

- Laser marking/engraving

- Plating

- Coating

- Brushing