Sheet Metal Fabricator in China

TENRAL Is a professional sheet metal fabrication manufacturer in China, providing customized sheet metal fabrication services for customers in various fields. Whether you need an entire product to build from scratch or a single component created from existing drawings, we have the tools and expertise to get the work done quickly and efficiently. Our internal capabilities include precision stamping, bending and laser cutting to ensure your parts meet the exact specifications of your application. We pride ourselves on providing rugged, moulable, and cost-effective custom fabrics to help your business succeed.

What is sheet metal fabrication?

Sheet stock is initially obtained in a flat state and then undergoes a series of progressive steps to be cut and formed into its final state. The first step in a typical sheet metal project is sheet cutting, which involves using a shear, laser, waterjet, plasma, or punch press to create the internal holes and edge features of the part. This process is also called blanking. After the blank has been produced, the next step is to form the sheet metal using various tools, with the most common being a brake. A brake press, whether manual or automated, can create a desired angular bend by using die inserts, transforming the two-dimensional sheet into a three-dimensional object. Sheet metal forming can bend the part in multiple directions, allowing for the creation of simple parts such as brackets, as well as highly complex geometries that may require custom die tools. Once the tools are in place, producing subsequent sheet parts during production becomes very cost-effective. As a result, sheet metal fabrication and forming are ideal for low to high volume production.

Laser cutting

Laser cutting is an advanced metal cutting technology that utilizes a high-energy density laser beam to rapidly heat and vaporize metal materials in a very short period of time, thereby achieving precise cutting of metal in various shapes and sizes without physical contact. Compared to traditional mechanical cutting methods, laser cutting has many advantages, including fast cutting speed, high precision, smooth and high-quality cuts, and a small heat-affected zone.

- Max cutting thickness of carbon steel: 25 mm

- Max cutting thickness of stainless steel: 14 mm

- Max cutting thickness of copper: 10 mm

- Max cutting thickness of aluminum: 14 mm

- Precision: ±0.03 mm

- Max pipe length: 6300 mm

- Pipe diameter: 16-240 mm

- Precision: ±0.03 mm

Metal bending

When metal sheet is subjected to pressure from the die on the bending machine, it first experiences elastic deformation, then plastic deformation. In the initial stage of plastic bending, the sheet metal is free to bend. As the die applies pressure to the sheet metal, it gradually comes into close contact with the inner surface of the V-shaped groove in the lower die, and the radius of curvature and the bending lever arm also gradually decrease. Continue to increase the pressure until the end of the stroke, which makes the upper and lower dies and the sheet metal three points fully in close contact. At this point, a V-shaped bending process is completed, which is commonly known as bending.

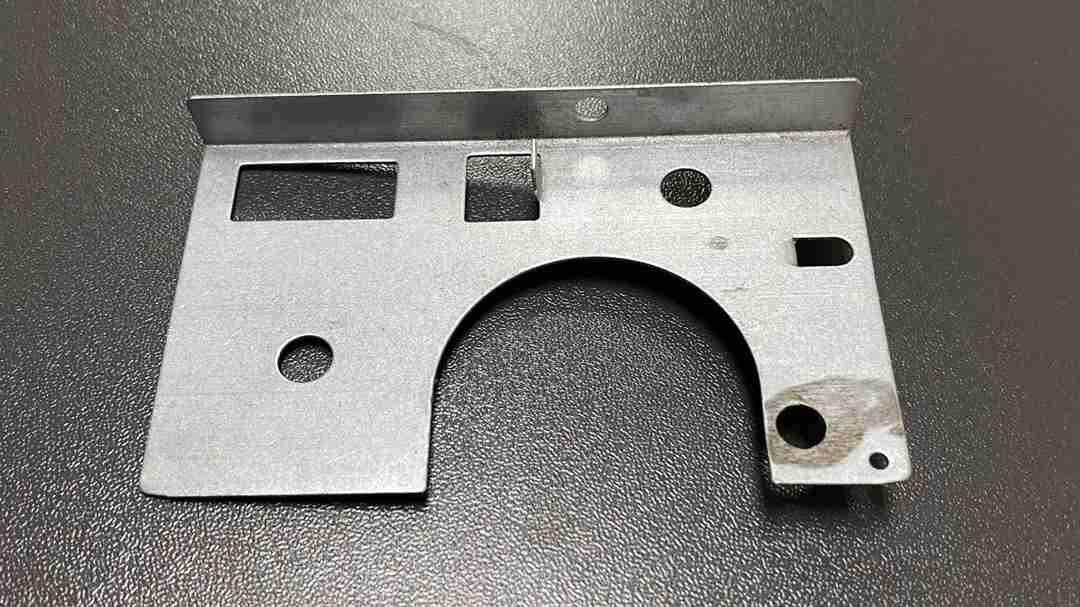

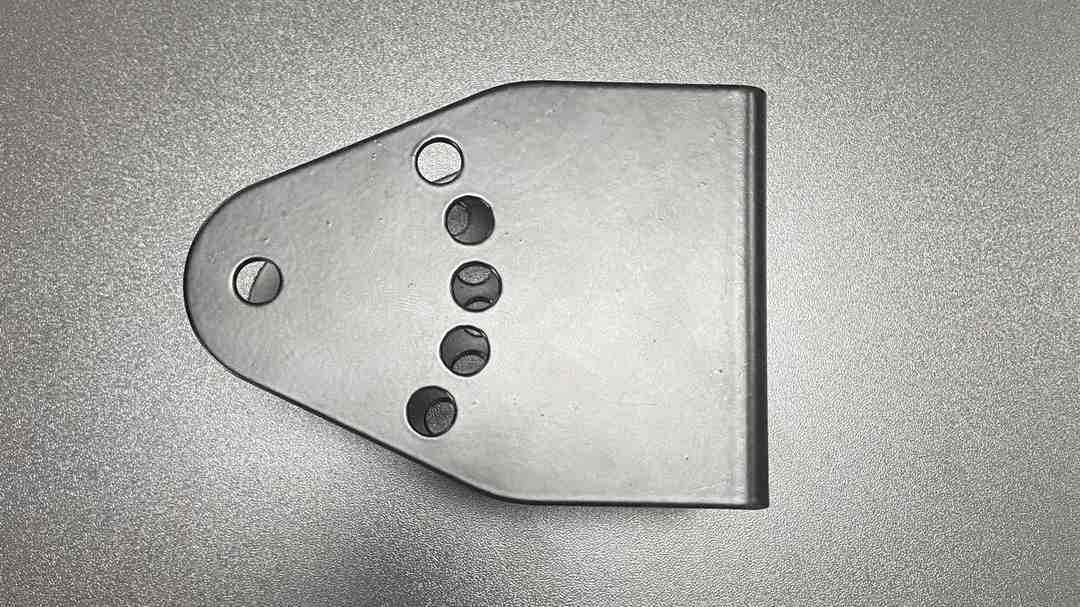

Cases that were allowed to be published

Sheet metal fabrication materials

Metal stamping and sheet metal fabrication are indispensable links in manufacturing, involving a variety of materials such as steel, aluminum alloy, copper, stainless steel and titanium alloy. Due to the unique physical and chemical properties of different materials, corresponding processing processes and tools need to be adopted. As a professional metal processing service provider, TENRAL can master the characteristics of various materials on the basis of rich industry experience and professional technology, and provide customers with high-quality metal stamping and sheet metal processing services.

Mild steel is an alloy steel with a low carbon content, usually between 0.008% and 2.06%. Due to its low carbon content, low carbon steel has high ductility and malleability, and has good toughness and wear resistance. Therefore, it is widely used in various mechanical parts, automotive parts, building structures, bridges, ships, tools and instruments and other manufacturing fields. In addition, the mechanical properties of low carbon steel can be further improved by heat treatment, such as improving strength, hardness and wear resistance.

Cold rolled steel is a kind of high-precision and high-gloss steel products that are processed by cold rolling process.It has excellent ductility and plasticity, and is widely used in the manufacture of various high-quality steel products, such as automobile bodies, building structures, household appliances and furniture.In addition, cold rolled steel also exhibits excellent corrosion resistance and wear resistance, and is often selected for the manufacture of industrial machinery and equipment that require long-term use and high reliability requirements.

Coated steel is a process that applies one or more layers of metal or non-metallic materials to the surface of steel, aiming to improve the corrosion resistance, wear resistance, oxidation resistance and other properties of steel. Coated steel is widely used in construction, automotive, aerospace and electronics and other fields.

Stainless steel is an alloy material, which mainly includes iron, chromium and nickel. It has characteristics such as corrosion resistance, wear resistance, ease of cleaning and maintenance, etc., so it is widely used in construction, kitchen appliances, chemical industry, medical treatment and food processing fields.

Aluminum alloy is a lightweight metal material widely used in the industrial field, and its main components include aluminum, copper, magnesium, and zinc. Compared with traditional steel materials, aluminum alloy has advantages such as light weight, strong corrosion resistance, good electrical conductivity, high strength, and easy processing. Therefore, it has been widely used in aviation, automotive, electronics, and construction.

Copper has excellent electrical conductivity, thermal conductivity and corrosion resistance, and is widely used in cables, pipes, appliances and decorations. In addition, red copper also shows excellent mechanical properties and malleability, and can be processed into various shapes and sizes. At the same time, as an environmentally friendly material, red copper can be recycled and has no pollution to the environment. Therefore, red copper is widely used in modern industry and life.

Brass is an alloy composed of copper and zinc, with a bright yellow luster and excellent electrical, thermal, and corrosion resistance. It is widely used in the manufacturing of various appliances, ornaments, and electronic devices. In addition, brass is also widely used in jewelry, sculpture, painting, and other artistic creations due to its outstanding artistic and ornamental properties.

Applications

TENRAL plays an important role in multiple industries, including automotive manufacturing, electronic devices, aerospace, medical equipment and building hardware. TENRAL is known for its high-quality, high-precision and high-efficiency metal stamping technology, contributing to the provision of reliable metal parts in all industries.

Quality Policy

As a leading supplier of metal stamping, TENRAL always prioritizes quality as our core business policy. From the procurement of raw materials to the manufacturing of finished products, all our dedicated employees take full responsibility and approach each product with utmost seriousness. Our highly skilled engineers closely collaborate with our diligent inspectors to establish comprehensive product quality documentation right from the initial stages, meticulously documenting every step of the manufacturing process for each individual product. We consistently adhere to ISO9001 quality requirements in order to effectively control and maintain superior quality standards for every single item we produce.

Metal Finishing Services

TENRAL is dedicated to providing metal surface processing services, aiming to give metal parts higher practical value and aesthetic value.We use advanced processing technology to finely grind, polish and spray metal parts, making their surfaces smooth and shiny, while enhancing their corrosion resistance and wear resistance.In addition, we also provide a variety of colors and textures of spraying services to create a unique visual effect, to meet the personalized needs of customers.Whether it is industrial machinery, auto parts, electronics or household items, TENRAL can bring the ideal surface treatment effect and make the products have a competitive advantage in the market.