The strategy of welding and Utilization of Precision Sheet Metal Fabricators and Custom Metal Fabricators

Introduction:

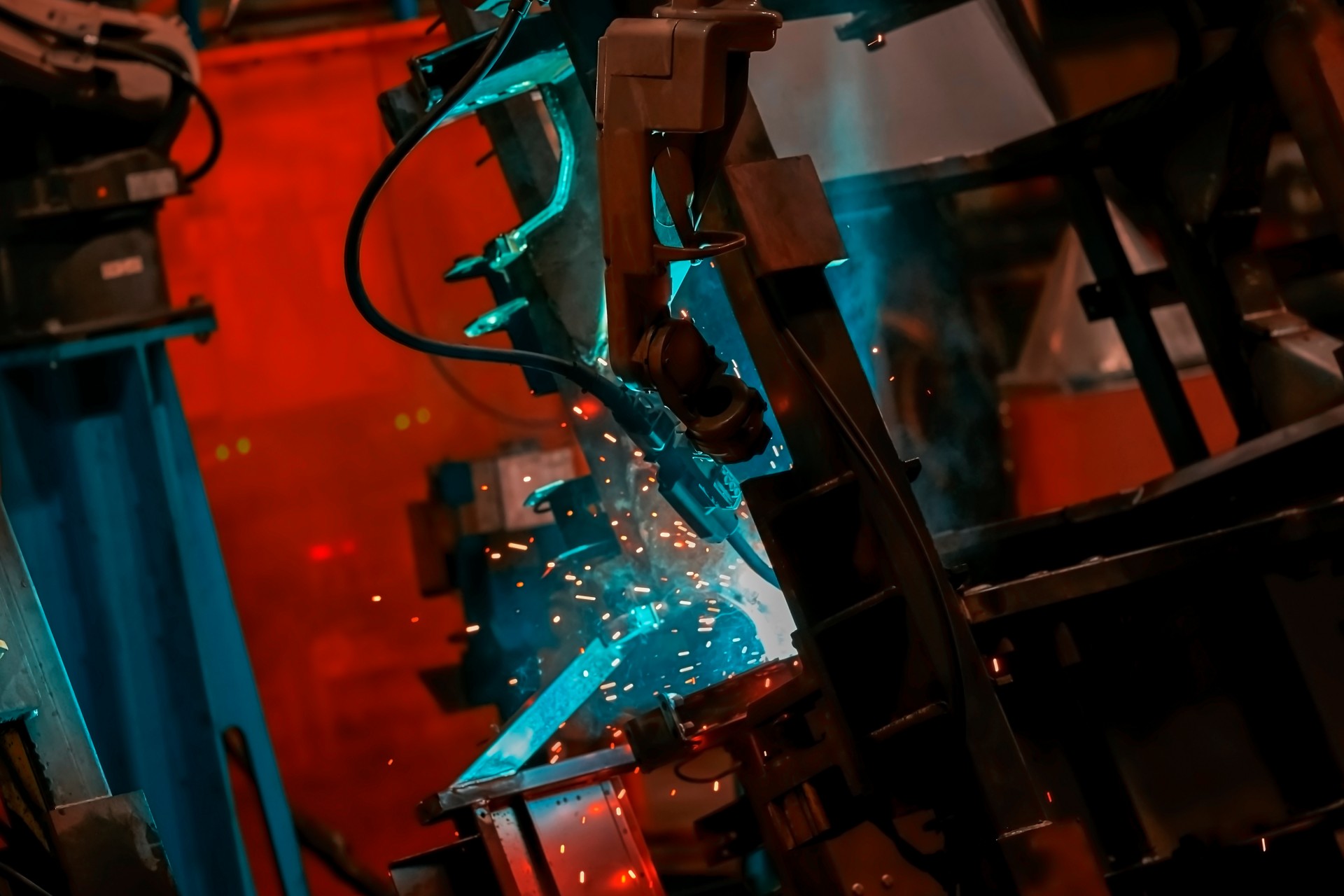

The interrelated disciplines of precision sheet metal fabrication, welding, and metal fabrication form the foundation of many companies. These trades are essential to defining our world, from electronics and healthcare to aircraft and the automobile industry. This introduction will examine the creativity, skill, and influence of precision sheet metal fabrication and bespoke metal fabrication.

Thin metal sheets must be carefully manipulated during precision sheet metal manufacturing to build complicated components and structures. A thorough grasp of materials, equipment, and processes is necessary for this specialized process. The final goods meet the strict criteria and tolerances because of the precision and accuracy attained in this art.

Custom metal fabrication and precision sheet metal fabricators have a significant influence. They act as the foundation for crucial sectors like aerospace, automotive, electronics, healthcare, and others. Precision sheet metal fabricators and custom metal fabricators continue to create our environment by producing sturdy and aesthetically pleasing metal buildings and goods.

Precision Sheet Metal Fabrication: The Art and Science

The laborious manipulation of thin metal sheets to produce complicated and exact structures is the fascinating result of the marriage of art and science known as precision sheet metal fabrication. It is a specialized craft that calls for a thorough grasp of tools, materials, and methods.

Precision sheet metal fabrication’s fundamental goal is to turn unfinished metal sheets into useful and visually pleasing items. To guarantee that the finished product adheres to strict standards and tolerances, each process necessitates a high degree of competence, accuracy, and attention to detail.

The ability to realize intricate patterns is what distinguishes precision sheet metal production as an art form. Fabricators must accurately and skillfully translate technical drawings and plans into real constructions. They must have attention to detail, be skilled, and comprehend various metals’ intrinsic qualities and constraints.

In addition, precision sheet metal manufacturing also has a strong foundation in engineering principles and scientific theories. Fabricators need to be well-versed in production procedures, structural mechanics, and material qualities. They must carefully take into account elements, including the end product’s structural integrity, corrosion resistance, thermal expansion, and load-bearing capacity.

Applications for the Fabrication of Precision Sheet Metal

Due to its adaptability, accuracy, and durability, precision sheet metal manufacturing has several uses in a variety of sectors.

When it comes to the aircraft industry, where strong yet lightweight metal structures are crucial, precision sheet metal fabrication is key. Wings, fuselages, and engine casings are some of the parts that are made using it. Aerospace systems’ security and effectiveness are guaranteed by the accuracy and sturdiness offered by sheet metal production.

Making electronic enclosures, chassis, and cabinets requires precise sheet metal fabrication. These metal frameworks offer defense, shielding, and heat dissipation for fragile electronic components and circuitry. Electronic equipment performs properly and lasts a long time thanks to the exact measurements and complex designs made possible by sheet metal production.

Precision sheet metal fabricators are utilized in the healthcare sector to create medical equipment, including diagnostic tools, surgical tools, and hospital furnishings. To satisfy the strict standards of the healthcare industry, it is essential to be able to produce hygienic, corrosion-resistant, and customized metal components.

Applications for precision sheet metal production go beyond these fields, with usage in areas including architecture, telecommunications, energy, and defense. This procedure is crucial for making practical, dependable, and aesthetic metal goods because of its adaptability and accuracy.

Precision sheet metal fabricators’ jobs

To ensure the high quality and accuracy of manufactured metal components, a precision sheet metal fabricator is essential. They are highly qualified individuals with experience using CAD software, interpreting blueprints, and operating metalworking equipment. They painstakingly adhere to technical drawings and requirements to shape and assemble metal sheets with extraordinary accuracy, making precise material selections and using cutting-edge procedures. A precision sheet metal fabricator must carry out intricate fabrication procedures, including cutting, bending, shaping, welding, and finishing, while following rigid tolerances and quality requirements.

Bringing Custom Metal Fabrication into the Open

- Exploring the World of Custom Metal Fabrication: Above and Beyond the Ordinary

Beyond traditional production techniques, custom metal fabricators provide countless opportunities for designing one-of-a-kind, personalized metal items. This subsection draws attention to the special nature of bespoke metal production and its capacity to materialize creative concepts.

- The Collaborative Method: Transforming Ideas into Reality

Close communication between customers, architects, engineers, and fabricators is a must for custom metal fabrication. The collaboration process is explored in this subsection, which highlights the significance of comprehending customers’ concepts, turning them into workable designs, and assuring successful project execution.

- Bringing Form and Function Together: Custom Metal Fabrication’s Artistry

Custom metal fabricators combine form and function to produce beautiful and useful metal things. They have outstanding artistic talents. This subsection examines the creative elements of bespoke metal manufacturing, exhibiting the skill, consideration, and imagination required to realize ideas.

- Masterpieces on Display: Outstanding Projects in Custom Metal Fabrication

The noteworthy projects that best represent the skills and talents of bespoke metal fabricators are highlighted in this section. It displays a variety of uses, including architectural constructions and art installations, showcasing the adaptability and creative ability of bespoke metal production.

- Breaking New Ground: Custom Metal Fabrication Innovations and Techniques

Fabricators push the limits of what is possible to ensure that custom metal fabrication is always evolving. Innovative methods, tools, and materials that revolutionize the industry are examined in this topic. These advancements improve productivity, accuracy, and design options.

- Every Industry Can Benefit from Custom Metal Fabrication: Uses and Benefits

Numerous sectors, including those in architecture, interior design, automotive, and other fields, are served by custom metal fabrication. The benefits of bespoke metal fabrication in many industries are covered in this subsection, which also emphasizes how it offers specialized solutions to problems that are one of a kind.

Conclusion:

In conclusion, welding and metal fabrication is a fascinating trade that blends creative vision, technical proficiency, and precision engineering. It goes beyond normal manufacturing procedures, enabling the production of distinctive and customized metal goods that satisfy customers’ individual demands and ambitions. Custom metal fabricators work closely with customers, architects, and engineers to complete projects. They create exceptional creations that perfectly combine form and function thanks to their expertise in metalworking equipment, materials, processes, and creative sensibility. Custom metal fabricators demonstrate the endless potential of metal as a medium with everything from architectural structures to elaborate art installations. Custom metal fabrication has a bright future as long as the sector embraces new technology and pushes the envelope. Custom metal fabricators will continue to influence our world by bringing beauty, utility, and innovation to many sectors through their inventive methods, environmentally friendly practices, and dedication to workmanship.