Understanding the Application of Metal Stamping Parts

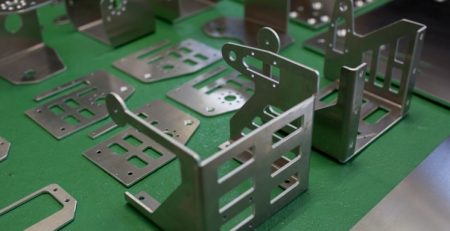

In metal stamping, metal is formed into specific shapes or designs using a die and press machine. It can be used to manufacture a wide range of parts and components for a variety of industries. It is very common for metal stamping parts to be used in a variety of industries, and this article will explore a few of them.

A metal stamping part is commonly used in the automotive industry. Application of metal stamping parts is a process used to produce a wide range of parts, including fenders, doors, hoods, and other body panels. In addition to valve covers, oil pans, and cylinder heads, metal stamping is also used to manufacture engine components. As a result of metal stamping, large volumes of parts can be produced in the automotive industry, thereby reducing costs.

As well as heat sinks, connectors, and shielding, metal stamping is used in the electronics industry to produce various electronic components. Electronic components produced by metal stamping are of high quality and meet the specifications required. The precision and accuracy of metal stamping ensures that they meet the specifications.

The construction industry also uses metal stamping parts. These parts are used in various construction projects, such as building frames, bridges, and other infrastructure projects. Metal stamping can be used to produce brackets, supports, and fasteners.

To ensure their safe and effective use in medical procedures, metal stamping parts are used to produce a wide range of surgical instruments and medical devices.

Lastly, metal stamping parts are also used in the aerospace industry. The aerospace industry demands parts that are strong, lightweight, and durable. Parts such as brackets, panels, and other components are made from metal stamping.

How is metal stamping used in manufacturing?

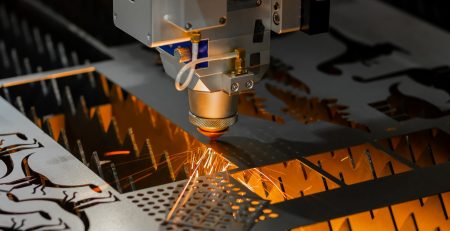

The metal stamping process involves applying pressure and a die to a piece of metal in order to create a specific shape or design. During the press process, the metal is placed between the two parts of the die, and the press is used to apply pressure, causing the metal to take on its shape. A wide range of industries use this process to manufacture parts and components.

A metal stamping process makes it possible to manufacture parts in large quantities, making it a cost-effective process for industries that need large quantities of parts on a regular basis. As well as producing parts of high quality and meeting the specifications, metal stamping can also produce parts with high precision and accuracy.

It is possible to use metal stamping to produce a wide range of automotive parts, including brackets, fasteners, connectors, body panels, electronic components, and medical surgical instruments. It is essential for the safe and effective operation of various products and systems to produce durable, reliable, and high-quality parts, which can be produced using metal stamping in these industries.

Overall, metal stamping is a versatile manufacturing process that is essential to the production of a wide range of parts and components for different industries. A popular choice for large-volume production of parts, it is cost-effective, precise, and accurate, while its versatility makes it possible to produce parts for many different applications.

What are some examples of industries that use metal stamping parts?

Many industries use metal stamping parts due to their versatility and cost-effectiveness, including automotive, electronics, construction, medical, and aerospace.

Automotive body panels, such as fenders, hoods, and doors, are made with metal stamping parts. In addition to valve covers, oil pans, and cylinder heads, metal stamping is also used to manufacture engine components. These parts are produced in large quantities for automotive applications.

In the electronics industry, metal stamping parts are used to produce connectors, heat sinks, and shielding that meet the specific requirements of electronic devices.

Various structural components, such as brackets, supports, and fasteners, are manufactured using metal stamping parts in the construction industry.

To ensure their safety and effectiveness in medical procedures, metal stamping parts are used to manufacture surgical instruments, implants, and diagnostic equipment.

Metal stamping parts have some advantages over other manufacturing methods.

Many industries choose metal stamping because of its many advantages over other manufacturing methods. One of the main advantages of metal stamping is its cost-effectiveness. As a highly automated process, Application of metal stamping parts can produce large quantities of parts, thereby reducing the unit cost. Furthermore, metal stamping produces complex parts with high precision and accuracy, which minimizes waste and ensures consistent quality.

In addition to its versatility, metal stamping can also be used to produce parts from aluminum, copper, steel, and brass, among other metals. As a result, specific application requirements can be met, such as strength, durability, and conductivity, for parts produced using this process.

Due to the use of high-speed presses that can produce thousands of parts per hour, metal stamping is a highly efficient manufacturing method, with a much higher production rate than other methods. In industries like the automotive and electronics industries that require large volumes of parts, metal stamping makes sense.

As a final point, metal stamping is highly customizable, allowing parts to be produced in a variety of shapes, sizes, and designs.

What are the advantages of metal stamping for large volume production?

In metal stamping, a press and a die are used to shape a piece of metal into a specific shape or design. The process can be automated and highly efficient, allowing large volumes of parts to be produced in large quantities.

Typically, metal stamping dies are constructed of hardened steel and are designed to produce specific shapes and designs. Using a press, the metal takes on the shape of the die after it has been positioned between the two parts of the die. It is possible to repeat this process multiple times per minute, allowing parts to be produced in large quantities.

The use of high-speed presses is another factor that makes it possible to produce large volumes of parts. These presses can produce thousands of parts per hour, significantly increasing production.

A single die can also be used to produce multiple parts simultaneously with metal stamping. In progressive stamping, a strip of metal is fed through a series of dies that gradually shape it into the desired shape. In a single pass, multiple parts can be produced, further increasing the production speed.

Metal stamping is commonly used to produce what types of electronic components?

The process of metal stamping is used to shape a piece of metal into a specific design or shape, which is then used in electronic devices as a component.

In electronic devices, connectors are one of the most common components produced by metal stamping because they allow wires and cables to be connected. With metal stamping, connectors can be produced in a wide variety of shapes and sizes, with high precision and accuracy, ensuring compatibility with a wide range of electronic devices.

Electronic devices use heat sinks to dissipate heat and prevent damage to sensitive components, which are another component produced using metal stamping. Heat sinks can be produced with complex shapes and designs with Application of metal stamping parts, ensuring that they are effective in cooling electronic devices.

In addition to shielding components, metal stamping is also used for electronic devices. Shielding components protect electronic devices from electromagnetic interference, ensuring their proper operation. With metal stamping, shielding components can be produced precisely and accurately, ensuring their effectiveness in protecting electronic devices.