Unleashing the Artistry of Sheet Metal Fabricators: Exploring the Craftsmanship of Custom Metal Fabrication Shops

Introduction

Sheet metal fabricators are vital to the development of the structural landscape in the fields of manufacturing and construction. It is both a science and an art for them to manipulate metal expertly and turn it into complex shapes. These talented artisans give life to raw materials via their devotion and creativity, whether they are creating architectural marvels or engineering useful components.

In this article, we delve into the intriguing world of sheet metal fabricators and investigate the specialized services provided by bespoke metal fabrication businesses. We’ll explain how metal sheets are turned into pieces of art that are both useful and beautiful, displaying the sophisticated methods used by these talented craftspeople.

Sheet metal fabrication as an art

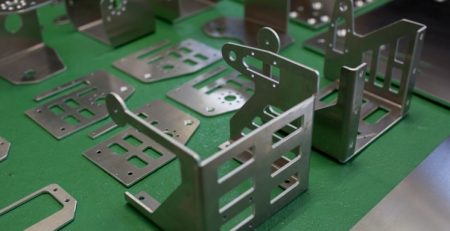

Cutting, bending, and shaping metal sheets to make a variety of goods is the work of sheet metal fabricators, which is a broad discipline. Sheet metal fabricators use their knowledge to turn unfinished materials into working parts that adhere to exact requirements, producing everything from clear brackets to intricate architectural designs.

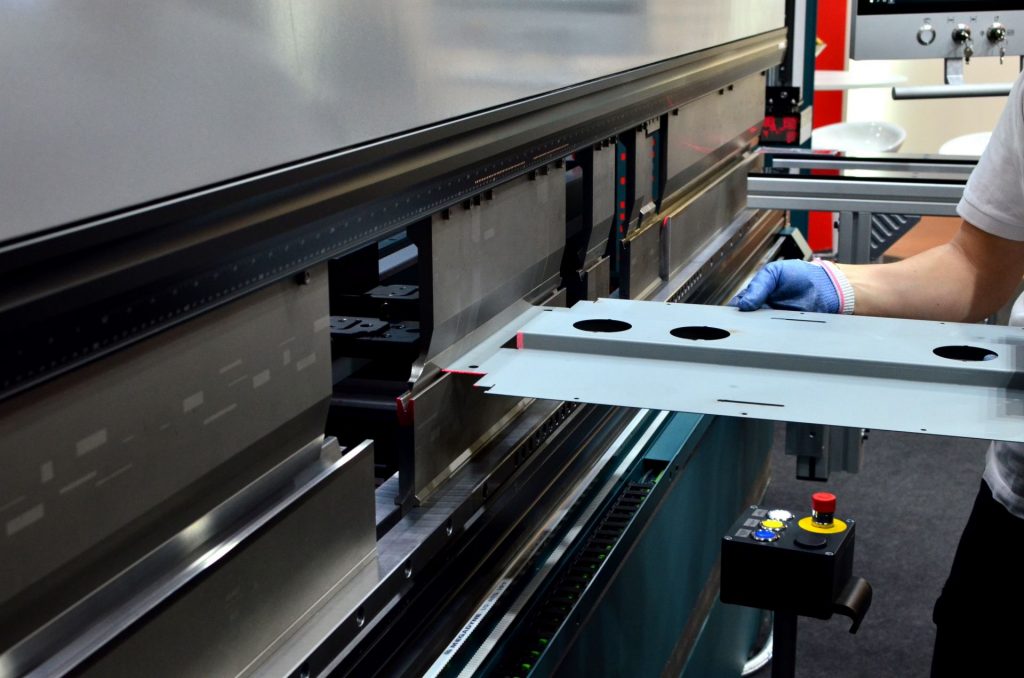

The basic processes for cutting and shaping sheet metal, including shearing and laser cutting, as well as bending and rolling, are examined in this section. We’ll also detail the value of exact measurements and how to utilize specialized equipment to guarantee accurate results.

Shops for Custom Metal Fabrication: Beyond Standardization

There are instances when off-the-shelf solutions fall short, even if mass production has a place in many sectors. Custom metal fabrication shop businesses flourish in this area because they provide specialized services that are tailored to each project’s specific needs. These firms put innovation and personalization at the forefront, whether it be through unique architectural characteristics or specially-made industrial equipment.

Working with bespoke metal fabricators has benefits, which we’ll discuss in this section. We’ll talk about the collaboration process between clients and fabricators, focusing on the value of talking to each other and comprehending the project’s objectives. Additionally, we will emphasize the importance of knowledge and imagination in transforming abstract concepts into real-world mental miracles.

Materials and Methods in Metal Fabrication

Accurate techniques and methods are required to get the desired result of metal fabrication. Various types of materials are utilized depending based on qualities and essentialities. A distinct manufacturing procedure is needed to shape, connect, and finish each material.

Cutting methods, including shearing, sawing, laser cutting, and water jet cutting, are used to produce accurate forms and sizes. Complex curves and angles may be made using forming and bending techniques, which make use of equipment like press brakes and rollers. To provide structural integrity, metal parts are fused using joining procedures, including welding, soldering, and brazing.

The look of the metal is improved as it is shielded against corrosion or wear by surface treatments and finishes such as plating, painting, powder coating, grinding, and polishing. Material can be removed to obtain desired forms and dimensions using machining procedures, including milling, drilling, and turning.

In metal fabrication, considerations including the intended use, required strength, durability, aesthetics, and budget play a role in the selection of materials and fabrication techniques. When transforming raw metal into functional and appealing products, skilled fabricators know the selection of the right materials, comprehension of their qualities, and the use of the best procedures.

Modern Metal Fabrication Techniques

The industry has been entirely transformed by the advancements in accuracy, efficiency, and adaptability made possible by modern metal production processes. With the help of advanced techniques, many complex designs and complicated structures can be easily made. Through the elimination of human labor and the augmentation of speed and precision, automation and robots have increased production. Aside from that, virtual prototyping and optimization are made possible by simulation and computer-aided design (CAD) software, which reduces mistakes and wasteful material use. To meet the changing needs of many sectors while keeping high quality and efficiency, current processes have created new possibilities in the field of metal fabrication.

The Collaborative Process: From Idea to Creation

To turn an idea into a physical reality, customers, designers, and custom metal fabricators come together as part of the collaborative process of metal fabrication. Effective teamwork ensures the project achieves the required objectives and standards from the beginning of ideation to the end of manufacture.

A detailed conversation between the client and the fabricator kicks off the procedure. Understanding the client’s goals and needs in terms of functionality and aesthetic preferences is necessary for this. The fabricator can understand the client’s requirements and provide insightful and helpful ideas when there is clear communication and active listening.

A vital part of the collaborative process is design. Designers collaborate closely with the customer and fabricators to produce thorough plans, drawings, and 3D models.

Thanks to these visual representations, all stakeholders can visualize the finished product and make defensible choices about the components, dimensions, and production processes.

Fabricators start the prototype step as soon as the design is complete. Testing the product’s functioning, fit, and shape is made easier with prototypes. Before moving on to the final fabrication, custom metal fabricators work together with the customer and designers to make any required alterations or improvements.

Collaboration and continual communication are crucial throughout the production process. Fabricators notify clients of the status and resolve any problems or changes that may occur. Collaboration makes sure the project stays on track, completes before the deadline, and maintains high standards.

Problem-solving is another aspect of the collaborative process. During fabrication, difficulties or unanticipated impediments may appear. Fabricators may solve problems more effectively by working together and being transparent with one another.

Conclusion

The unsung heroes that created some of the most amazing items and buildings in the contemporary world are sheet metal fabricators and bespoke metal fabrication businesses. In sectors ranging from building and architecture to automotive and aerospace, their enthusiasm, knowledge, and devotion to their craft make them invaluable.

In sheet metal fabrication, there is much more to the art than just bending and cutting metal sheets, as we’ve seen throughout this essay. It calls for a rigorous procedure that combines technical expertise, original thought, and in-depth material knowledge. Individuals and companies may let their imaginations run wild and realize their metal-based dreams with the help of knowledgeable custom metal fabricators, producing outcomes that are as beautiful and practical as they are beautiful.

Take a minute to recognize the skill and commitment of the sheet metal fabricators who made it all possible the next time you are astounded by a wonderfully built metal structure or depend on a precisely manufactured metal component.