Precision Metal Fabrication: A Look at the World of Various Metal Fabricators

Introduction:

From aerospace and automotive to electronics and telecommunications, precision metal fabrication is essential in many different sectors. It entails the production of premium, uniquely designed metal structures and components, frequently utilizing cutting-edge methods and specialized tools. The diversified metal fabricator, a flexible producer that provides a wide variety of services to fulfill the particular demands of customers, is a significant participant in this market. In this essay, we’ll dig into the world of precision sheet metal fabrication and examine the value and potential of diverse metal fabricators.

Understanding the fabrication of precision metal

The process of producing high-quality metal components and structures with extraordinary accuracy and precision is referred to as precision metal fabrication. It uses various approaches and specialized tools to get the intended result. This careful procedure is necessary for functioning and safety in the aircraft, automotive, electronics, and telecommunications sectors.

It is impossible to overestimate the value of accuracy in metal manufacturing. It guarantees that the finished goods fulfill the necessary fit, performance, and size requirements. Precision metal fabrication ensures consistency and homogeneity in mass manufacturing to facilitate interchangeability and effective assembly.

Precision metal fabrication also significantly reduces waste, reduces material utilization, and improves overall cost-effectiveness. Businesses may increase productivity, reduce mistakes, and provide their consumers with products of the highest caliber by optimizing the production process and attaining high precision. Precise metal fabrication plays a crucial role in the industrial sector. It requires complex procedures and attention to detail to make accurate, high-quality metal components that guarantee use, dependability, and cost-effectiveness.

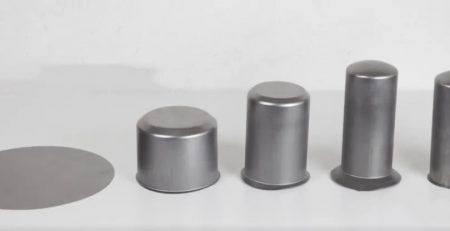

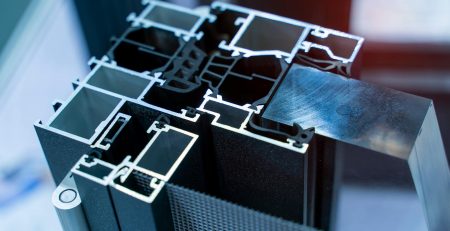

Precision sheet metal fabrication’s function

Precision sheet metal fabrication is a specialized area of metal fabrication that concentrates on employing thin sheets of metal to create precise and accurate components and structures. Several techniques, such as cutting, bending, shaping, welding, and finishing, are used to form the metal sheets into the necessary forms and dimensions. Precision sheet metal fabrication is the basis for the manufacture of intricate and specialized metal goods, ranging from electronics enclosures and automotive parts to aircraft components and medical equipment. It is a vital option for sectors that need accurate and dependable metal components due to its versatility in working with different materials, including steel, aluminum, and copper, as well as its use of cutting-edge procedures and tools.

Integrated Metal Fabricators: The Master of Versatility

Diverse metal fabricators are famous for their adaptability knowledge in the realm of precision metal fabrication.

Diversified metal fabricators excel at handling challenging tasks and customizing solutions, which is one of their key differentiators. For prototypes, specialized designs, and large-scale manufacturing runs, they are exceptional at offering solutions. They are capable of taking on projects of various complexity due to their extensive knowledge of various operations, including cutting, bending, welding, and finishing.

Working with diverse metal fabricators offers several benefits. Customers profit from their technological know-how, affordable solutions, and prompt delivery. They are an excellent partner for businesses looking for high-quality precision metal fabrication due to the breadth of their services and their capacity to manage a variety of projects.

Quality of the metal

Assuring high-quality goods is crucial in the manufacturing of precision metal. Strict testing, inspections, and adherence to predetermined norms and requirements are all part of quality control in the manufacture of metal. Manufacturers may ensure that the completed goods meet or surpass customer expectations by putting strict quality control methods in place that allow them to spot and fix any problems or flaws.

Certification

Certifications provide stakeholders and consumers further comfort that the dedication to quality is genuine. Certifications like ISO 9001:2015 show adherence to global standards for quality management systems. Companies seeking these certificates must put in place reliable quality control procedures, ongoing improvement programs, and efficient documentation systems.

Various sectors may need industry-specific certifications in addition to ISO 9001. As an illustration, AS9100D compliance is frequently required in the aerospace sector. This standard focuses on quality management systems for aviation, space, and defense organizations. Like ISO/TS 16949, ISO 13485 is only applicable to companies that make medical devices, while ISO/TS 16949 is required for companies that make cars.

Certifications provide manufacturers with a competitive advantage in the market in addition to improving their reputation and trustworthiness. They receive trustworthy items according to industry standards, and through rigorous quality control procedures, they promise them.

The benefits and advantages of precision metal fabrication

Numerous sectors choose precision metal production because of its many advantages and benefits. To begin with, it offers improved design freedom and customization choices, enabling the development of complicated and sophisticated components that adhere to certain specifications. Second, precise manufacturing techniques are time and money-effective, maximizing production schedules and reducing material waste. Thirdly, precise metal fabrication’s consistency in quality and dependability guarantees that the fabricated components adhere to rigid industry requirements and provide excellent performance. Precision manufacturing methods also make it possible to produce robust and lightweight parts, increasing the overall efficiency of the product and easing weight-related restrictions.

Precision Metal Fabrication Technologies

Processes are being streamlined, efficiency is increasing, and human error is declining thanks to automation and robots. Making complicated metal components with sophisticated geometries possible through additive manufacturing or 3D printing reduces material waste and provides design freedom. The sector is prepared to gain from higher production, decreased costs, and the flexibility to fulfill ever-changing client expectations as these technologies continue to advance.

Precision Metal Fabrication in the Future

Precision metal fabrication has a bright future ahead of it as technology and manufacturing methods continue to progress. Production will be further streamlined through automation and robots, improving productivity and lowering costs. The use of additive manufacturing, which enables sophisticated and personalized designs with less material waste, will spread. Predictive maintenance will be made possible through digitalization and IoT integration, which will improve connection and data-driven decision-making while streamlining industrial operations. The usage of cutting-edge materials and alloys will increase, providing better durability and performance. Overall, enhanced automation, creativity, sustainability, and the capacity to produce extremely complex and individualized metal will characterize the future of precision sheet metal production.

Conclusion

In conclusion, precision metal fabrication is an essential component of contemporary production, and varied metal fabricators are essential to satisfy the requirements of many sectors. Their knowledge, range of services, and dedication to quality allow manufacturing of highly precise metal components that spur innovation and advancement. Precision metal fabrication has a bright future ahead of it as new technology and innovations continue to transform the sector and promise increased productivity, sustainability, and ground-breaking solutions.