Benefits of Laser Cutter for Sheet Metal

A laser cutter for sheet metal is a very precise and highly recommended tool for cutting and designing metal sheets. A high-powered laser is used for the cutting of sheet metal and also a high degree of accuracy can be achieved using this tool.

The laser cutter for sheet metal works by directing a focused beam of light onto the metal surface, that melts, vaporizes, or burns the material, that makes the cut precise and accurate.

The use of a computerized system is the main part of this process. Automated machines allow high speed and good efficiency in the process of cutting. Laser cutter for sheet metal can be used with a variety of metals, including stainless steel, copper, and aluminum, and can easily be cut through every size or thickness.

The applications of laser cutters for sheet metal are in numerous industries of automobiles and electronics components and architectural elements.

The use of laser cutters for sheet metal in the automobile industry has several advantages over traditional cutting methods, such as increased precision, speed, and the ability to cut complex shapes and patterns.

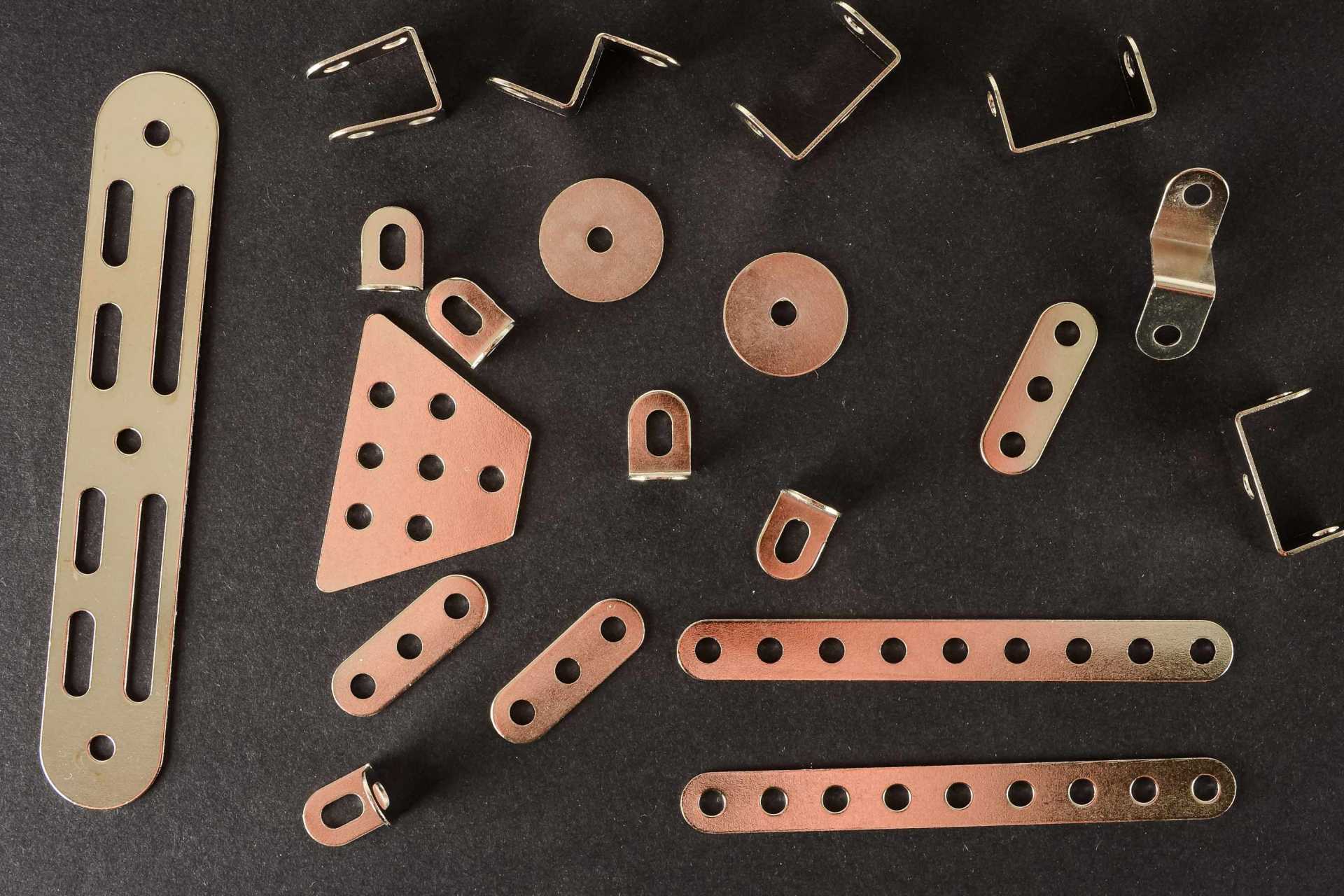

In sheet metal fabrication, a laser cutter for sheet metal is used to cut out parts such as car body panels, chassis components, brackets, and other structural elements. The laser cutter uses a computer-controlled laser beam to cut through the sheet metal, creating precise and accurate cuts that are often used for high-volume production.

A Laser cutter for sheet metal is particularly useful in the automobile industry because it can cut a variety of materials, including aluminum, stainless steel, and other alloys that are commonly used in car manufacturing. Laser cutters for sheet metal can also be used to create intricate designs, such as car logos, emblems, and other decorative elements.

One of the main advantages of a laser cutter for sheet metal technology is that it reduces the need for post-processing of the cut parts. Laser cutters produce clean, burr-free edges, which reduces the need for grinding, deburring, or other finishing processes. This not only saves time but also improves the quality and consistency of the final product.

Another advantage of laser cutter for sheet metal is their high-speed cutting capability. This is particularly useful in the automobile industry, where large volumes of parts need to be produced quickly and efficiently. Laser cutters can cut through thick sheet metal quickly, reducing production times and increasing efficiency.

- Cutting car body panels: Laser cutter for sheet metal are used to cut out car body panels, such as doors, fenders, hoods, and trunks. The laser beam can cut through various materials, including aluminum, stainless steel, and other alloys, creating precise and accurate cuts. This is particularly important in the manufacturing of car body panels, where accuracy and consistency are critical.

- Cutting chassis components: A laser cutter for sheet metal is also used to cut chassis components, such as brackets, suspension parts, and engine mounts. These parts are critical to the performance and safety of the vehicle, and laser-cutting technology ensures precise cuts that meet exact specifications.

- Cutting decorative elements: Laser cutters are used to create decorative elements on car parts, such as logos, emblems, and other designs. The laser beam can cut intricate shapes and patterns quickly and accurately, resulting in high-quality, visually appealing parts.

- Cutting complex shapes: Laser cutters can cut complex shapes and contours that are difficult or impossible to achieve with traditional cutting methods. This allows manufacturers to create innovative designs and improve the overall performance of car parts.

- Prototyping and customization: Laser cutters are also useful for prototyping and customizing car parts. Manufacturers can create prototypes quickly and efficiently, allowing them to test and refine their designs before committing to large-scale production. Customization is also possible with laser cutting technology, as parts can be cut to specific dimensions and shapes to meet the unique needs of individual customers.

Laser cutter for sheet metal is widely used in the aerospace industry for the manufacturing of sheet metal parts. Here are some of the main uses of laser cutters for aerospace sheet metal fabrication:

- Fuselage components: Laser cutters are used to produce sheet metal parts used in the construction of aircraft fuselages. These parts include frames, stringers, and skin panels. Laser-cutting technology enables precise cuts and contours that meet the exact specifications required for aerospace parts. This ensures that the parts fit together perfectly and perform well in flight.

- Engine parts: Laser cutters are also used to produce sheet metal parts used in aircraft engines. These parts include turbine blades, compressor discs, and combustion chamber components. Laser-cutting technology enables the production of intricate shapes and contours that are essential for high-performance aerospace engine parts.

- Structural elements: Laser cutters are used to produce sheet metal parts used in the construction of structural elements of aircraft, such as brackets, beams, and stiffeners. Laser-cutting technology enables the production of strong, lightweight parts that can withstand the stresses and strains of flight.

- Landing gear components: Laser cutters are used to produce sheet metal parts used in the construction of landing gear components. These parts include struts, braces, and brackets. Laser-cutting technology enables the production of parts with precise dimensions and contours that are essential for the safe and reliable operation of landing gear systems.

In summary, a laser cutter for sheet metal technology is an important tool in the automobile industry for sheet metal fabrication. Its high precision, speed, and versatility make it a valuable asset in the production of car body panels, chassis components, and other structural elements. Laser cutters also reduce the need for post-processing of the cut parts, which saves time and improves the overall quality of the final product. TenraL is also providing this valuable service to its customers and their work efficiency is great. Their products are of great quality and they are providing the products at your doorstep. They design different types of parts using laser cutters for sheet metal. If you want any help or information about TenraL services don’t hesitate, feel free to contact us and do visit our website. Your query is our preference.