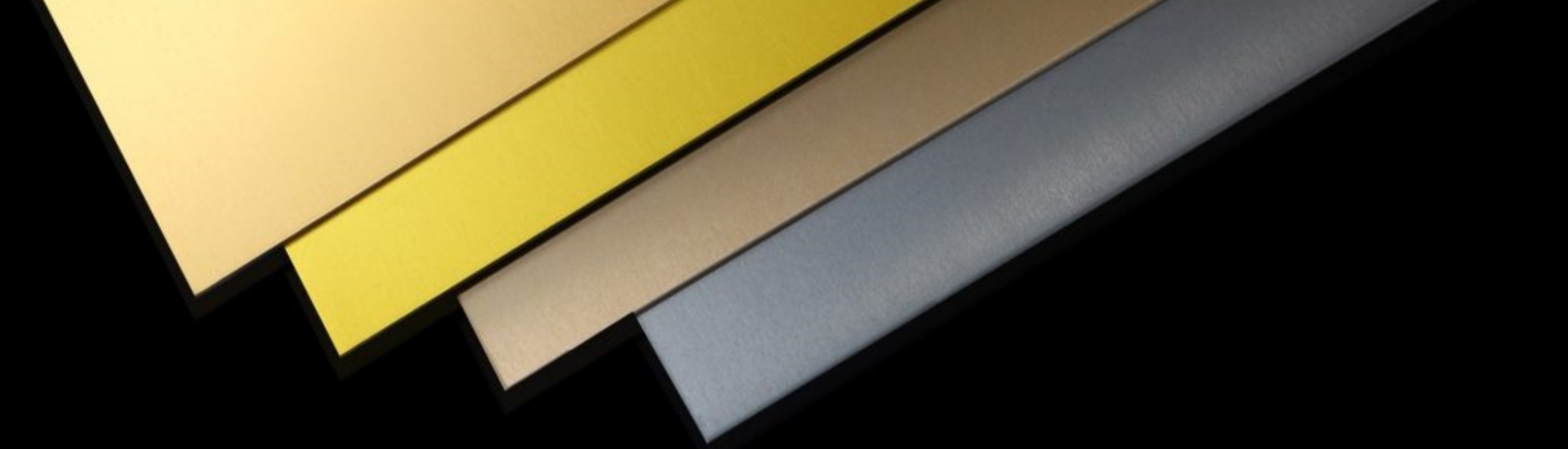

Best Materials for Sheet Metal Stamping & Fabrication

If you are stepping into the field of sheet metal stamping and fabrication, you must know about raw material getting in used. You must give the quality of the raw materials the highest importance because that affects the quality of the stamping directly and the best quality comes out only when you have used the best.

The way to choose the best materials for sheet metal stamping is confusing because there of many options to choose from like different raw metals, their alloys, and combinations.

Today, we will take you through the list of all the best materials for sheet metal stamping and fabrication that you need to pay attention to.

Copper alloys

The most common and easily accessible raw material for sheet metal stamping includes copper alloys. This includes elements like brass, nickel silver, bronze, etc. They give a lot more versatility and flexibility when it comes to production results.

Following are a few characteristics of copper worth highlighting:

- Good conductivity

- Corrosion resistant

- Antibacterial characteristics

- Non-magnetic

- Non-sparkling, etc.

But, they are also quite softer than the other metals, which explain why they aren’t suitable for strength-based metal stamping elements.

Steel alloys

Moving on we have the steel alloys, which are probably the most durable and tensile of them all. Elements like stainless steel account for the most common raw material under this.

Some of the factors that make them a priority choice include:

- Strong metal

- Versatility

- Corrosion resistant

- Durable

What’s great about stainless steel stamping is its wide range of uses. They can be used for the manufacturing of different industry elements and for simply constructing the sophisticated parts of certain metal-based machines.

Aluminum alloys

When it comes to strength-based or foundation-based metal stamping requirements, aluminum alloy takes the cake in that case. They do have a lot of similar properties like copper and steel alloys raw materials, which explains why they are known to provide the “best of both worlds.”

Some of the factors that explain why they are so popular for metal stamping are:

- Lightweight

- Durable

- Corrosion resistant

- Highly malleable

- Can take on additional load

Also, you have to keep in mind that aluminum is a good conductor of heat and electricity, which makes it a good raw material for metal stamping for certain custom items.

Specialty metals

While the above three raw materials are the most commonly used elements, there are a few additional options that also deserve a shoutout. They include titanium or nickel-based alloys. These are used quite specifically and for very intricate construction and metal stamping requirements.

If you are new to the whole ordeal of metal stamping and have been wondering about the different types of raw materials, we hope this explains it all in detail. Some of the factors are a bit confusing but the more you understand about the benefits of each element, the easier it should become for you to execute the metal stamping process.