Custom metal stamp parts for the Appliances industry

In today’s competitive world, businesses across various industries are always on the lookout for ways to stand out from the crowd. The appliances industry is no exception. With so many manufacturers offering similar products, it can be challenging to differentiate oneself from the competition. However, there is a simple yet effective way to do just that – through the use of custom metal stamps. Custom metal stamps offer a unique opportunity to add a personal touch to appliances and make them stand out from the rest. They allow manufacturers to add distinctive logos, designs, and even serial numbers to their products, making them more recognizable and memorable to customers. Moreover, custom metal stamps are a cost-effective way to enhance brand identity and increase brand awareness. In this article, we will discuss how custom metal stamps are helping the appliances industry to stand out and gain a competitive edge.

What is custom metal stamping?

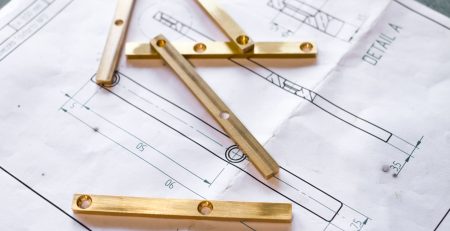

It is a manufacturing process in which metal sheets or coils are fed into a stamping press, and a custom-designed die or mold is used to shape and cut the metal into a specific form. The metal stamping process involves applying high pressure to the metal, which causes it to be formed, bent, or cut into the desired shape.

Custom metal stamping can be used to create a wide variety of metal components, ranging from small, intricate parts to large, complex pieces. Custom metal stamping is used in a variety of industries, including the Appliance industry, where it is used to produce a wide range of components for appliances such as refrigerators, washing machines, and air conditioners.

Custom metal stamp parts for the Appliances industry

Custom metal stamp parts are widely used in the Appliance industry. Here are some examples of the appliances in which metal stamp custom parts are used.

Kitchen equipment

Metal-stamped parts are used to create components in various kitchen appliances such as food processors, blenders, mixers, and toasters. For example, metal stamped blades, covers, and other parts are used in food processors and blenders to chop and mix food. With help of metal stamping precise parts can be formed that perfectly fit to required place and help in good processing of the appliance. A custom selection of materials makes these appliances more durable.

- Dishwasher – Custom metal stamp parts are used to create the outer panels, control panels, and internal components of dishwashers. These parts include spray arms, supports, and brackets. These precise and quality products that are produced with the process of metal stamping enhance the quality and working of the dishwasher.

- Washing machine – Custom metal stamp parts are used to create the outer panels, doors, and internal components of washing machines. These parts include drum shafts, agitator blades, and supports. With help of metal stamping desired shape, size and quality products can be achieved which helps to improve the quality and durability of washing machines.

- Refrigerators parts – Metal-stamped parts are used to create the outer panels, shelves, and drawer handles for refrigerators, as well as the heat exchangers and compressor brackets that are essential to the refrigerator’s cooling system.

- Water heater – Metal-stamped parts are used to create the outer panels, supports, and brackets for water heaters. These custom metal stamp parts of the water heater are made of material that doesn’t get rusted soon which overall increases the lifespan of the water heater.

- Air conditioning – These Customized metal stamped parts are used to create the outer casings and internal components of air conditioning units, such as the heat exchangers, compressor brackets, and fan blades. These custom parts are made up of good quality material that also increases the durability of the air conditioners.

Is metal stamp custom parts good for the appliance industry

Metal stamp parts are very beneficial for the appliance industry. They help the Appliance industry in multiple ways. There are several reasons why metal stamp custom parts are good for appliances.

- Precise – Metal stamping allows for the precise, accurate production of complex parts, which is essential in the Appliance industry. The industry requires parts that fit together perfectly to ensure reliable and efficient operation and metal stamping allows for tight tolerances and consistent quality.

- Durable – Custom metal stamped parts are strong and durable, which is crucial for appliances that are subject to daily wear and tear. They can withstand high temperatures, pressure, and mechanical stress, ensuring long-lasting performance.

- Cost-effective – Metal stamping is a cost-effective manufacturing method for producing large quantities of parts. This allows Appliance manufacturers to keep costs down while producing high-quality, consistent parts.

- Customized – Custom metal stamped parts can be designed and produced to meet specific requirements, including size, shape, and finish. This allows Appliance manufacturers to differentiate their products and create a unique look and feel for their brands. The use of these custom-designed parts will help them to stand out in the crowd.

From where do you should buy custom metal stamp parts

These parts are going to be their identity so the selection of a trustable manufacturer that fulfills all the requirements of the clients is essential. There are several factors that buyers should consider when buying custom metal stamp parts, including quality, lead time, pricing, and customer service.

Conclusion

Custom metal-stamped parts are essential to the efficient and reliable operation of these appliances. These custom-designed parts offer several benefits to the Appliance industry, including precision, durability, cost-effectiveness, and customization. They are an essential part of the manufacturing process, enabling Appliance manufacturers to create high-quality, reliable, and distinctive products that meet the needs of their customers.