Stamping parts are the production technology of product parts with a specific shape, size, and performance. With this power of conventional or special stamping equipment, the sheet metal is directly subjected to the deformation force and deformed in the mold. Sheet metal, die, and equipment is the three elements of stamping processing. Stamping is a kind of metal cold deformation processing method. Therefore, it is called cold stamping. It is one of the main methods of metal plastic processing (or pressure processing) and belongs to material forming engineering technology.

Catalogue

Properties of stamped parts

Application of stamping parts

The Bottom Line

Properties of stamped parts

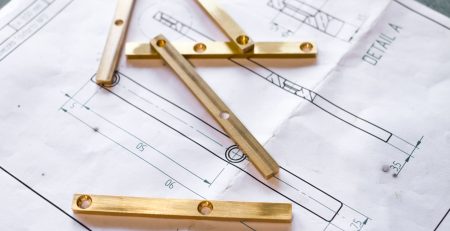

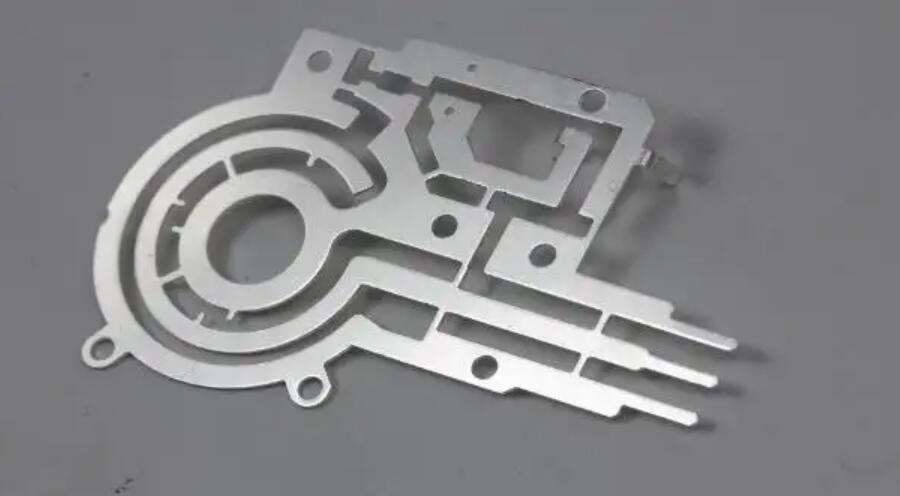

The precision stamping parts have the characteristics that they are thin, uniform, light, and strong. Stamping can produce workpieces with reinforcing ribs that are difficult to manufacture by other methods to improve their rigidity. Due to the use of precision molds, the accuracy of the workpiece can reach the micron level, the repetition accuracy is high, and the specifications are consistent. Holes, sockets, bosses, Etc. can be punched out. A metal sheet’s surface and internal properties significantly influence the quality of stamping products.

In addition to heavy plate forming by water press, the stamping equipment usually adopts the stagnant press. They were focusing on the high-speed multi-station stagnation press, the equipment configuration, such as uncoiling, collection of finished products, escort, and other stagnation. The mold library, quick mold change placement, and computer tube bundles can form a high-efficiency passive stamping processing line. Under the condition of processing hundreds of stamping parts per minute, the stamping and other processes can be completed quickly.

Application of stamping parts

In the world’s steel, more than half of the steel is made of plates, most of which are finished products after stamping. The automobile body, radiator plate, steam drum of steam boiler, container shell, iron core silicon steel sheet of motor, and electric appliance are all stamped. There are also many stamping parts in instruments, household appliances, office machines, safekeeping utensils, and other products. Stamping is an efficient processing method. With compound die, multiple stamping operations can be completed on one press to complete the automatic generation of materials. It has a fast generation speed, long rest time, and low processing cost. It can process hundreds of pieces per minute and is liked by many processing plants.

The Bottom Line

Stamping parts are the most widely used in hardware processing. It’s found that under room temperature, steel / non-ferrous metal and other sheet metal dies are formed into specific shapes by the press. It will improve the processing efficiency of some parts and make many parts more precise.