Tenral: Precision Metal Stamping Parts Manufacturer

The natural compounds on the earth’s crust that are found in the form of metal ores, that are associated with each other and many other elements as well. These elements can also be found naturally in the rocks that are washed by surface water and groundwater as well as in the atmospheric dust.

The job of metal tamping companies is to is to supply and manufacture metals according to their needs in the market. Tenral is a precision metal stamping parts manufacturer and supplier company in the market.

They have been in this business and have been providing sheet metal fabrication along with CNC machine services. They also work in producing precision metal stamping components for clients in the automotive, lighting, construction, and other industries.

The computer-aided design (CAD) and computer-aided manufacturing (CAM) processes are used to create the stamping tool. The need for precision in each strike and punch of the tool necessitates a computerized process.

The tenral’s have their workshop where all of the metal products are manufactured for various uses. They have a team of members who are professional in their job and quite reliable at the same time. All the workers in the workshop work with safety equipment as well.

Metal manufacturing capacity at Tenral

Through their production facilities, Tenral offers our customers specialized metal fabrication solutions, that can produce the most complex parts from a variety of steels including stainless steel or cold rolled steel as well as other materials like aluminum and brass.

Some of the metal fabrication solutions are:

- Precision metal stamping

- Custom sheet metal fabrication

- CNC machining

- Tooling

- Metal finishing

Precision metal stamping

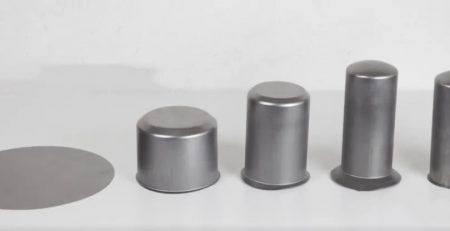

Flat metal sheets are subjected to intense pressure during the procedure in order to transform them into a certain shape. There are numerous steps and methods involved in a complex manufacturing process such punching, blanking, embossing, coining, flanging, piercing, and bending.

All the components can be slowly molded using progressive dies in a succession of steps during the stamping operation, or it can also be molded to the required shape in a single stamping press stroke.

The method of “pressing” or “cold-forming” allows flat sheet metal to be transformed into the necessary part or component with the aid of dies and stamping presses.

When it comes to metal formation, stamping describes the procedure, where a producer uses unique tooling and stamping methods to create parts that satisfy their clients’ criteria.

Services of metal stamping

Precision metal stamping parts manufacturer Tenral, offers press capacity offers specialized industrial metal stamping solutions for both basic and complex designs, using hydraulic presses with capacities ranging from 80 tonnes to 200 tonnes and presses with capacities between 32 tonnes and 150 tonnes.

They can produce the necessary stamping dies in-house using high-tech tool steel, which allows them to offer high-quality goods with the appropriate tolerances. They also make welding jigs in their workshop along with other sheet metal production tools. This process is quite well known in the manufacturing industries.