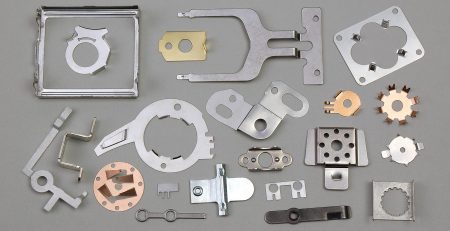

Best Sheet Metal Stamping Guides for Beginners

Getting started with sheet metal stamping isn’t the easiest, especially if you don’t have any formal knowledge about the process. If you are venturing into the industry thinking about profitability, you’d have to strengthen your knowledge first.

From identifying the best quality sheet metal to the dyes that are used in the stamping process, there are several factors that you have to pay close attention to

To simplify the process for you, we have curated this beginner’s guide that explains all the details about sheet metal stamping.

What are the types of sheet metal stamping?

Before you master the art of sheet metal stamping, you must understand the basics. To be fair, there are quite a few different types and they can get a little confusing if you aren’t that knowledgeable about the subject.

The most common type of stamping is called blanking, which involves the stamping press to punch hard on the metal sheet to bend it. The bending process, as it suggests, bends the metal to accommodate the stamping parts.

Unlike bending, which is done in a straight line, flanging involves bending the metal in a curved line and involves the use of complex materials. Embossing involves engraving on metal sheets and is done for creative elements.

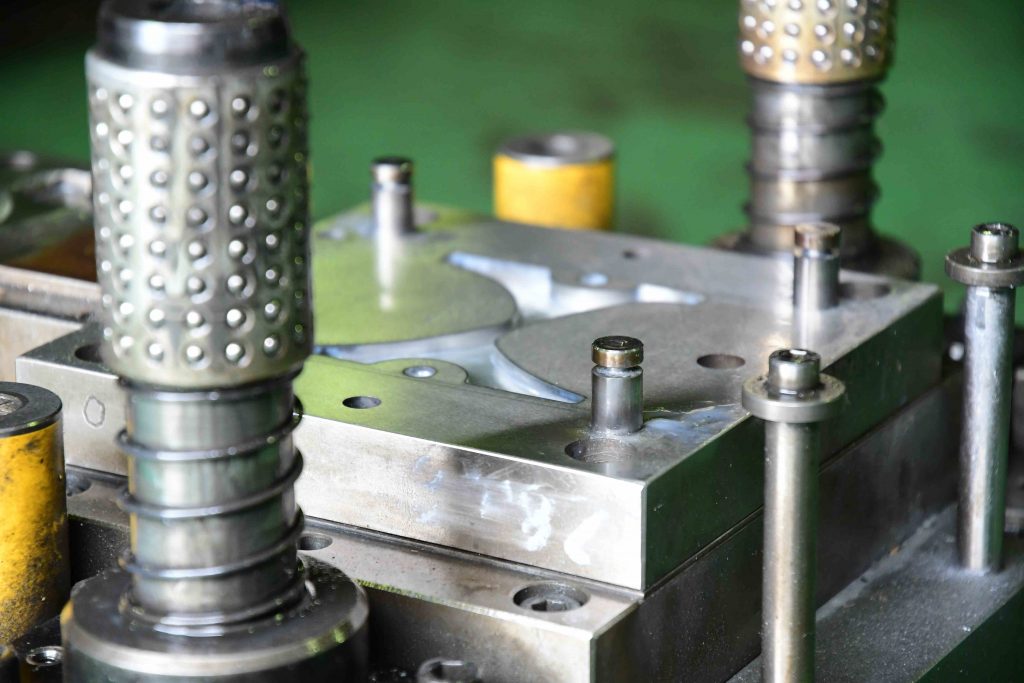

What are sheet metal stamp dies?

When you are new to the world of metal stamping, chances are that you will be confused about the metal stamp dies and it makes total sense. So, let us explain that too.

Dies are the elements that ensure that the sheet stamping is done in a precise manner and according to the accurate dimensions as suggested by the customers. Some of the common elements that make up the die include the cavity and the corresponding punch.

In most cases, these elements are made using CNC aluminum for heightened durability and flexibility of use.

What are the materials used for sheet metal stamping machines?

When you are considering investing in a customized sheet metal stamping machine, there are a few standard materials that you need to be mindful of. They include:

- Cold rolled steel

- Hot rolled steel

- Aluminum

- Galvanized

- Stainless steel

- Brass, etc.

Which one you choose for the stamping process depends on what the customers have asked from you. In most cases, aluminum and stainless steel are the most common.

Also, when you are venturing into the sheet metal stamping business, you must do proper market research to analyze what’s in demand and what’s not. Sometimes, we don’t realize and blindly venture into a new business with hopes that it will work out only for things to fizzle down.

As a beginner, mastering the process of stamping metal sheet stamping can take some time. The first step is to break down all the basics as we have mentioned in here. So, if you are confused about the process and have been wondering how to master things, we hope this answers all your queries and prepares you for what’s next.