Process Of Stainless Steel Metal Stamping

Metal stamping is a method that allows sheets of various metals to be shaped into a variety of shapes. This procedure falls under the category of coldworking. A metal stamper is used to execute metal stamping services. It is a tool that can cut through coils and sheets of tough metal.

Using this tool, many manufacturing Stamping Companies produce Precision Metal Products. Tenral is a company that produces stainless steel metal stamping that helps in the best manufacturing solutions. Customers can receive all types of metal services from them.

Tenral can provide its customers with a wide variety of metal stamping services thanks to its press capacities, which range from 32 tonnes to 150 tonnes, and hydraulic presses, which range in size from 80 tonnes to 200 tonnes.

With their greatest precision metal stamping firm, they produce the best metals with the cutting-edge technology for metal stamping, superior knowledge, and affordable prices. It is quite clear that the material is of high quality and proper maintenance keeps the products intact.

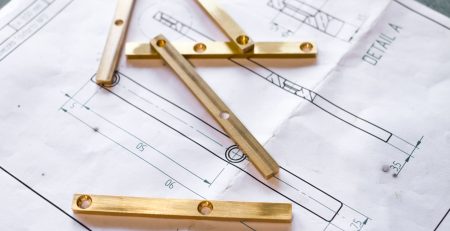

Steel stampings in workshop

Precision stamped parts made of stainless steel are Tenral’s area of expertise. A material with temperatures and a wide range of grades is called stainless steel. Each variety of stainless steel has distinct qualities and responds to stamping in a particular way.

Stainless steel metal stamping is one of the expertise areas of tenrals workshop. It has excellent properties and reactions are quite different during the process, such as the oxidation of resistance, the gloss maintenance, and rust avoidance. Additionally, it provides a visually pleasing appearance, boosting the products’ overall aesthetics.

Characteristics of stainless steel

To take advantage of its qualities, their stainless-steel stamping parts are quite frequently utilised in numerous fields:

- The mirror’s simplicity and appearance are lovely, and they can be polished to improve the finish or buy in a particular material.

- Heat resistance is made of stainless steel with a high concentration of chromium and nickel for particular heat stress.

- Health as a result of the convenient cleaning methods, which are favoured by the food and drug industries

One of the most widely used steel alloys for custom stamping is stainless steel. There are several types of stainless steel, including precipitation-hardened stainless steel, martensitic steel, austenitic ferritic (duplex) and ferritic steel.

Material grade of stainless steel

The first stage in creating a product is selecting the appropriate quality of stainless steel. In order to complete this process, understanding material grade is necessary.

- The 200 Series, which corresponds to grades 201 and 202 of the 300 Series, is frequently used as a less expensive substitute for nickel, which has poor corrosion resistance.

- Molybdenum is added to improve strength and corrosion resistance, this helps in resulting a grade of 316 in the 300 series that has suitable tensile qualities and corrosion resistance as well.

- Ferritic and martensitic stainless steel, grade 409 in the 400 series, is manganese-free.

- Heat-resistant chrome alloy steel from the 500 series.

- Martensitic precipitation-hardened stainless steel, 600 series.