Best 5 Metal Stamping Suppliers

The metal stamping industry has enjoyed steady growth over the past few decades because of its cost-effectiveness and mass-production capabilities. Due to several innovative technological developments, this industry has witnessed steady growth. The metal stamping industry has grown as robotics, automation, and numerical controls have improved precision and speed.

As compared to 2018, the market for metal stamping is expected to grow at a CAGR of 3.9% from 2018 to 2023, reaching USD 289.2 billion by 2023.

What is metal stamping?

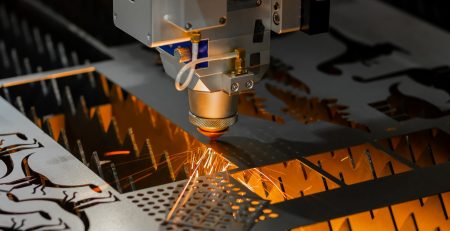

Metal stamping is a manufacturing process where metal sheets or coils are transformed into various shapes and sizes using a range of techniques, including punching, blanking, embossing, bending and coining. The process involves using dies and punches to cut or deform the metal into a desired shape or pattern. Metal stamping can be used to produce large volumes of parts quickly and cost-effectively, making it a common production method in industries such as automotive, aerospace, electronics, and medical equipment manufacturing.

What are the advantages and disadvantages of metal stamping?

Metal stamping has its own advantages and disadvantages. Some of the main advantages of metal stamping are:

Advantages:

- High accuracy: Metal stamping produces parts with high precision and accuracy, ensuring consistent quality throughout the production run.

- High volume: Metal stamping is a highly efficient process that can produce large volumes of parts quickly and at a low cost per part.

- Versatility: Metal stamping can be used to create a wide range of complex shapes and geometries, making it suitable for many different applications.

- Cost-effective: Because metal stamping is an automated process, it is relatively inexpensive compared to other manufacturing methods, especially for high-volume runs.

However, there are also some disadvantages to using metal stamping:

Disadvantages:

- Upfront costs: The initial tooling and setup costs for metal stamping can be relatively high, which can make it less economical for small production runs.

- Limited material selection: Metal stamping is typically limited to metals that are easy to work with, such as steel, aluminum, and copper. This means that certain materials such as composites or plastics cannot be worked on easily.

- Design restrictions: Certain designs may not be suitable for metal stamping due to the limitations of the tools and machinery used in the process.

- Lead time: The lead time required to set up metal stamping is often longer than other manufacturing processes, which can impact delivery times.

Overall, metal stamping can be an effective and efficient manufacturing process for high-volume production runs of accurately formed metal parts, but it may not be suitable for every type of product or application.

Best 5 Metal Stamping Suppliers

The following are the top 5 companies in the metal stamping industry that offer professional custom metal stamping services and excellent equipment.

1. Tenral

Website: https://www.tenral.com/

Tenral (the predecessor of PinCheng Hardware Products – the company founded in 2005) is a small metal stamping manufacturer and supplier, providing simple metal stamping parts to select domestic customers at a competitive price. The customer base of the company continues to expand as the company continues to grow. As a result, they made the big decision in 2010 that they would separate their company and set up Tenral as a separate company. It was decided that Pincheng would run the mainland China business, Tenral would run the international business, and the production division would remain the same. In order to expand their production, they have purchased stakes in other manufacturing companies, such as the fabrication of sheet metal and CNC machining. As a result of their continued growth, they now have more than a dozen manufacturing facilities, covering more than 70,000 square feet and employing more than 80 people. Having set up an internal tool shop in order to meet the diverse needs of their customers, they are now able to produce complex precision stamping tools in order to meet the needs of their customers.

2. Xiamen Qiangsheng Industry And Trade Co., Ltd.

Website: https://xmqsgm.en.alibaba.com/

Qiangsheng Industry & Trade Co., Ltd. (formerly Qiangsheng Industry & Trade company) has been providing high quality metal pressing parts since 1988. Lathe cutting tooling design and making, they have the capability to handle any order. Short delivery time , competitive price quote.

From simple flat cutting to precision metal pressing, they are capable of following up with customer requests by using different technologies (welding and riveting) to assemble these components and then zinc plating them as the final surface treatment. Electrophoresis, powder coating, painting, screen, etc.

Many of their products are used in the auto parts component, the building, plumbing, electrical, and electromechanical industry, as well as numerous exports to North America, Europe, Oceania, and the Middle East.

3. Shanxi Yunwei Industrial Co., Ltd.

Website: https://china-yunwei.en.alibaba.com/

The Shanxi YunWei Industrial Co., Ltd is an international supplier of castings, stamping parts, precision machining parts, and other industrial items. Managing the internal enterprise and monitoring product quality are always our top priorities. Their team of highly qualified and experienced engineers is responsible for designing, drawing, modifying, producing, and ensuring that all of our customers’ needs are met.

They have gained good reputation from their customers across the world due to advanced technology, years’ experience of fast and timely service, high quality products and highly efficient management.

4. Xiamen Mach Cnc Machining Master Co., Ltd.

Website: https://machcnc.en.alibaba.com/

The factory Xiamen Mach CNC Machining specializes in OEM Injection Molding and Metal Fabrication. The CEO & founder of MACH, Jason, began his machining career in 1995 as a designer & machinist. Therefore, MACH is able to solve most of the problems in this field.

Their main business is CNC Machining, plastic injection molding, and stamping parts. They have sophisticated CNC machining centers, engraving and drilling machines, lathes, mills, line-cutters, etc. Their machines and experienced employees enable them to perform repeat positioning within tolerances of 0.005mm, providing a strong guarantee for precision parts. In the manufacturing process of their products, they strive to exceed the expectations of their customers, employees, suppliers, and communities. In order to improve efficiency and ensure high and stable quality, they continue to adopt advanced production facilities. Their goal is to provide reliable, viable, and affordable molds, CNC machining parts, and fast sample service to all industries.

5. Qingdao Dmetal International Trade Co., Ltd.

Website: https://qddmetal.en.alibaba.com/

They are a manufacturer of metal and plastic spare parts using state-of-the-art testing facilities and have a strong technical team. In addition, their products are widely utilized in the car brake system as well as other industries. Their products feature a wide range, good quality, reasonable prices and stylish designs. The products they offer are widely recognized and trusted by users and can meet continuously changing economic and social needs.