Innovative Manufacturing Solutions: The Power of Progressive Die

When it comes to manufacturing solutions, there are few options that can match the power and versatility of progressive die technology. Progressive die manufacturing has been around for many years, and it has continued to evolve and improve with the times. The technology is known for its accuracy, speed, and cost-effectiveness, making it an attractive option for many industries. In this blog, we’ll take a closer look at the power of progressive die technology and how it can help businesses improve their manufacturing processes.

What is Progressive Die Technology?

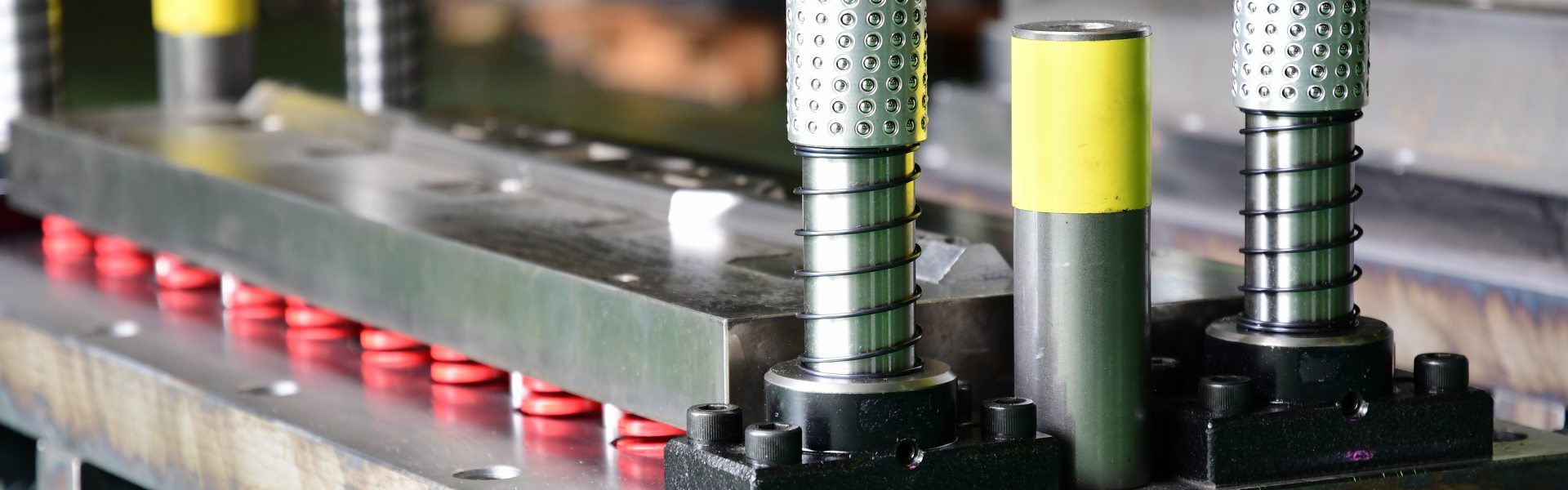

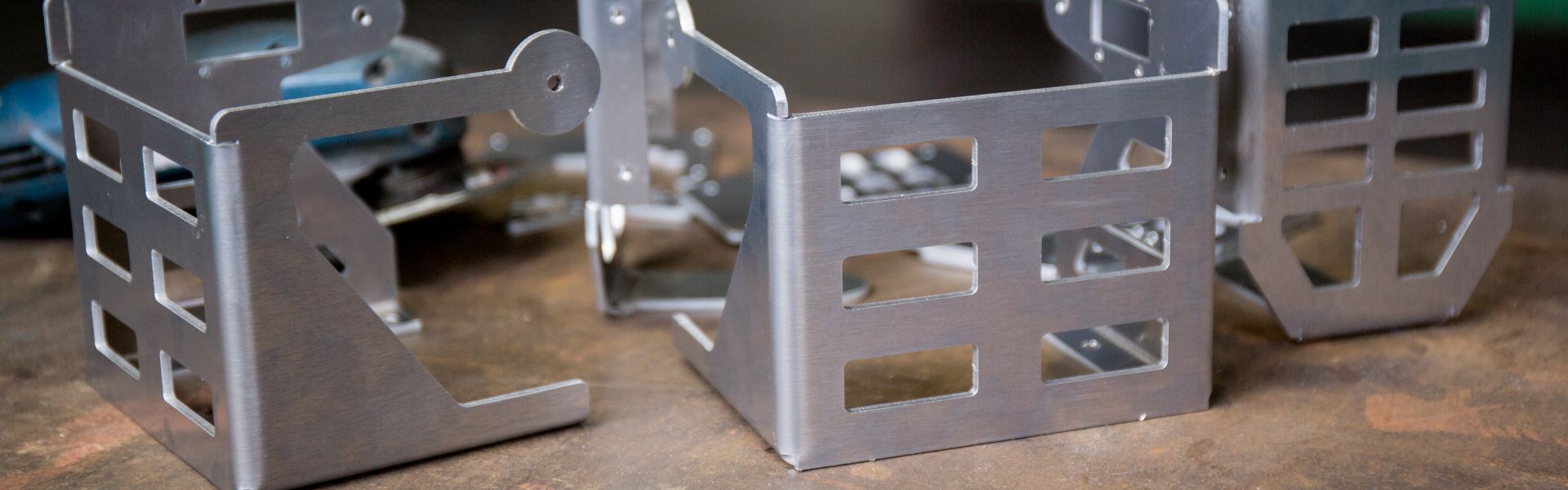

Progressive die technology is a manufacturing process that involves the use of a tool called a progressive die. The die is a metal stamping tool that is used to cut, shape, and form metal sheets into specific shapes and sizes. The progressive die is unique in that it can perform multiple operations at once, allowing for a faster and more efficient manufacturing process.

The progressive die is made up of several stations, each with its own cutting, shaping, or forming function. As the metal sheet moves through the die, each station performs its operation until the final product is complete. The result is a highly accurate and consistent part, with very little waste or scrap material.

Why is Progressive Die Technology Important?

Progressive die technology is important for a number of reasons. First, it allows for a faster and more efficient manufacturing process. With the ability to perform multiple operations at once, the progressive die can produce parts at a much faster rate than traditional manufacturing methods.

Second, the technology is highly accurate and consistent. Because the progressive die is a single tool that performs multiple operations, there is very little room for error. This means that the parts produced are highly precise and consistent, which is important for many industries.

Third, progressive die technology is cost-effective. Because the process is so efficient and produces very little waste, the cost per part is often lower than with traditional manufacturing methods. This makes it an attractive option for businesses looking to reduce their manufacturing costs.

How Do Progressive Die Techniques Work?

The progressive die process begins with a flat strip of metal being fed into the die. The first station in the die performs the initial cut and shape of the part. The part then moves to the next station where another operation is performed, and so on, until the final part is produced. The process is automated, allowing for high volumes of parts to be produced quickly and efficiently.

The Best of Progressive Die: Top 5 Picks

If you’re in the market for a high-quality progressive die, you want to make sure you get the best of the best. Progressive dies are essential tools for precision metal stamping, and it’s important to choose a manufacturer that uses top-notch materials and has a strong reputation for excellence.

At Tenral, we understand the importance of choosing the right progressive die for your needs. That’s why we’ve put together a list of our top 5 picks for the best progressive dies on the market today. Whether you’re looking for a die for high-volume production or a more specialized application, these picks are sure to meet your needs.

- Progressive Die

At the top of our list is the tenral progressive die. This die is known for its exceptional precision and reliability, making it a favorite among manufacturers in a variety of industries. With its high-quality materials and advanced design, the tenral progressive die is perfect for high-volume production runs and complex stamping projects.

- High-Speed Progressive Die

If speed is a top priority for your stamping operation, the tenral high-speed progressive die is an excellent choice. This die is designed for maximum efficiency, with a streamlined design that reduces material waste and speeds up production times. Plus, with its durable construction and low maintenance requirements, the Tenral high-speed progressive die is a cost-effective choice for high-volume production runs.

- Carbide Progressive Die

For applications that require extreme precision and durability, the tenral carbide progressive die is the way to go. Made from high-quality carbide materials, this die is designed to withstand even the most demanding stamping projects. With its superior wear resistance and long lifespan, the tenral carbide progressive die is a smart investment for any manufacturer.

- Heavy-Duty Progressive Die

When you need a die that can handle heavy-duty stamping projects, the tenral heavy-duty progressive die is the way to go. This die is built to withstand the toughest conditions, with a rugged design that can handle even the most challenging materials. Plus, with its advanced engineering and superior materials, the tenral heavy-duty progressive die delivers exceptional precision and accuracy on every stamp.

- Custom Progressive Die

Finally, if you have a specialized stamping project that requires a unique die design, the tenral custom progressive die is the way to go. Our team of experienced engineers and designers will work with you to create a die that meets your exact specifications, ensuring that you get the results you need for your application. With its tailored design and exceptional quality, the tenral custom progressive die is the perfect solution for any specialized stamping project.

Industries that Benefit from Progressive Die Technology

Progressive die technology can be used in a wide variety of industries. Some of the most common industries that benefit from the technology include:

Automotive Industry: The automotive industry is one of the largest users of progressive die technology. The technology is used to produce a wide variety of automotive parts, including engine components, body parts, and structural components.

Appliance Industry: The appliance industry also benefits from progressive die technology. The technology is used to produce parts for appliances such as refrigerators, ovens, and washing machines.

Electronics Industry: The electronics industry uses progressive die technology to produce parts for a wide variety of devices, including smartphones, computers, and televisions.

Medical Industry: The medical industry also benefits from progressive die technology. The technology is used to produce medical devices and components, including surgical instruments and implants.

Conclusion

In conclusion, progressive die technology is a powerful and versatile manufacturing solution that can help businesses improve their manufacturing processes. The technology is highly accurate, consistent, and cost-effective, making it an attractive option for many industries. With its ability to produce parts at a faster rate than traditional manufacturing methods, progressive die technology is sure to remain an important part of the manufacturing landscape for many years to come.